-

+84 982 384 688 - Mr. Thi | +84 982 803 586- Ms. Hoa

-

theptangiabao@gmail.com

-

Thứ 2 - Thứ 7 | 07:30 - 17:00

Ferritic/Austenitic (Duplex) Stainless Steel Electric Fusion Welded Pipe A928 Grade S32750

Product info

Product info

| Supplier: | Tapgroup internation.,JSC |

| Address: | Số 32 Lô N4D, đường X2A, Yên Sở, Hoàng Mai, Hà Nội |

| Phone: | 0084 933 86 77 86 |

| Email: | info@tapgroup.vn |

| Website: | https://supplier-pipe-tube-ongthep.com |

| Insurance: | 12 tháng |

| Status: | Mới 100% |

| Origin: | China, Korea, Malaysia, Thailand, Japan, EU, G7 |

| Name: | Ferritic/Austenitic (Duplex) Stainless Steel Electric Fusion Welded Pipe A928 Grade S32750 | |||||||||||||

| Type of Pipe | Electric Fusion Welded Pipe, A928 Grade S32750 | EFW Pipe, A928 Grade S32750 | ||||||||||||

|

Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition of Filler Metal1 This standard is issued under the fixed designation A 928/A 928M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.A superscript epsilon (e) indicates an editorial change since the last revision or reapproval |

||||||||||||||

| Pipe and Filler Metal Specifications | ||||||||||||||

|

UNS Designation |

Grade A |

ASTM Plate Specification No. and Grade |

A5.4 | A5.9 | A5.11 | A5.14 | A5.22 | A5.30 | ||||||

| Class | UNS | Class | UNS | Class | UNS | Class | UNS | Class | UNS | Class | UNS | |||

| S32750 | 2507 | A 240 S32750 | … | … | … | … | … | … | … | … | … | … | … | … |

|

AExcept as indicated, common name, not a trademark, widely used, not associated with any one producer. BA grade designation originally assigned by the American Iron and Steel Institute (AISI). |

||||||||||||||

| Heat Treatment | ||||||||||||||

|

UNS Designation |

GradeA | Temperature, °F [°C] | Quench | |||||||||||

| S32750 | 2507 | 1880–2060 [1025–1125] | rapid cooling in air or water | |||||||||||

| A Except as indicated, common name, not a trademark, widely used, not associated with any one producer. | ||||||||||||||

| B A grade designation originally assigned by the American Iron and Steel Institute (AISI). | ||||||||||||||

| Mechanical Tests Required | ||||||||||||||

|

Transverse Tension Test—One test shall be made to represent each lot of finished pipe. Transverse Guided-Bend Test—One test (two specimens) shall be made to represent each lot of finished pipe. Nondestructive Test—Each length of pipe shall be subjected to a hydrostatic test as defined in or, with the approval of the purchaser, each length of pipe having a wall thickness up through 0.165 in. (4.2 mm) shall be subjected to a nondestructive electric test as defined in. Hydrostatic Test—Each length of pipe shall be subjected to a hydrostatic test in accordance with Specification A 999/A 999M, unless specifically exempted under the provision of Pressure shall be held for a sufficient time to permit the inspector to examine the entire length of the welded seam. With the agreement of the manufacturer, the purchaser is permitted to complete the hydrostatic test requirement with the system pressure test, which may be lower or higher than the specification test pressure, but in no case shall the test pressure be lower than the system design pressure. Each length of pipe furnished without the completed manufacturer’s hydrostatic test shall include with the mandatory marking the letters NH. Nondestructive Electric Test—Each length of pipe shall be subjected to a nondestructive electric test in accordance with Practice E 426. For pipe up through NPS 4, the eddy-current test shall be applied to the total pipe area. For pipe larger than NPS 4, the eddy-current test is permitted, at the option of the producer, to be applied to the weld area only rather than the total pipe area. |

||||||||||||||

| Wall Thickness: Welded and Seamless Wrought Steel Pipe, ANSI /ASME B36.10M | ||||||||||||||

| SCH 5 | SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | |||||||||

| SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 160 | |||||||||

| SCH XXS | SCH XX.H | |||||||||||||

| Dimensions of Welded and Seamless Stainless Steel Pipe ANSI /ASME B36.19M | ||||||||||||||

| The decimal thickness listed for the respective pipe sizes represents their nominal or average wall dimensions. | ||||||||||||||

|

NPS Designator |

Outside Diameter | Nominal Wall Thickness | ||||||||||||

|

Schedule 5S mm |

Schedule 10S mm |

Schedule 40S mm |

Schedule 80S mm |

|||||||||||

| 1⁄8 | 10.29 | … | 1.24 | 1.73 | 2.41 | |||||||||

| 1⁄4 | 13.72 | … | 1.65 | 2.24 | 3.02 | |||||||||

| 3⁄8 | 17.15 | … | 1.65 | 2.31 | 3.20 | |||||||||

| 1⁄2 | 21.34 | 1.65 | 2.11 | 2.77 | 3.73 | |||||||||

| 3⁄4 | 26.67 | 1.65 | 2.11 | 2.87 | 3.91 | |||||||||

| 1.0 | 33.40 | 1.65 | 2.77 | 3.38 | 4.55 | |||||||||

| 11⁄4 | 42.16 | 1.65 | 2.77 | 3.56 | 4.85 | |||||||||

| 11⁄2 | 48.26 | 1.65 | 2.77 | 3.68 | 5.08 | |||||||||

| 2 | 60.33 | 1.65 | 2.77 | 3.91 | 5.54 | |||||||||

| 21⁄2 | 73.03 | 2.11 | 3.05 | 5.16 | 7.01 | |||||||||

| 3 | 88.90 | 2.11 | 3.05 | 5.49 | 7.62 | |||||||||

| 31⁄2 | 101.60 | 2.11 | 3.05 | 5.74 | 8.08 | |||||||||

| 4 | 114.30 | 2.11 | 3.05 | 6.02 | 8.56 | |||||||||

| 5 | 141.30 | 2.77 | 3.40 | 6.55 | 9.52 | |||||||||

| 6 | 168.28 | 2.77 | 3.40 | 7.11 | 10.97 | |||||||||

| 8 | 219.08 | 2.77 | 3.76 | 8.18 | 12.70 | |||||||||

| 10 | 273.05 | 3.40 | 4.19 | 9.27 | 12.70 | |||||||||

| 12 | 323.85 | 3.96 | 4.57 | 9.52 | 12.70 | |||||||||

| 14 | 355.60 | 3.96 | 4.78B | … | … | |||||||||

| 16 | 406.40 | 4.19 | 4.78B | … | … | |||||||||

| 18 | 457.20 | 4.19 | 4.78B | … | … | |||||||||

| 20 | 508.00 | 4.78 | 5.54B | … | … | |||||||||

| 22 | 558.80 | 4.78 | 5.54B | … | … | |||||||||

| 24 | 609.60 | 5.54 | 6.35 | … | … | |||||||||

| 30 | 762.00 | 6.35 | 7.92 | … | … | |||||||||

|

Schedules 5S and 10S wall thicknesses do not permit threading in accordance with the American National Standard for Pipe Threads (ANSI B1.20.1). These do not conform to the American National Standard for Welded and Seamless Wrought Steel Pipe (ANSI B36.10–1979). |

||||||||||||||

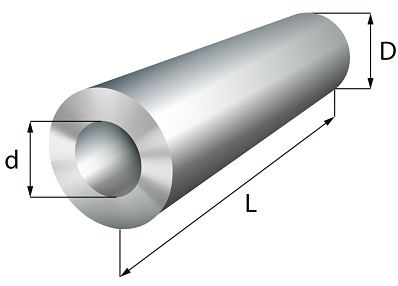

| Pipe Dimensions | ||||||||||||||

| NPS Designator | Wall Thickness | |||||||||||||

| Schedule 5S | Schedule 10S | |||||||||||||

| in. | mm | in. | mm | |||||||||||

| 14 | 0.156 | 3.96 | 0.188 | 4.78 | ||||||||||

| 16 | 0.165 | 4.19 | 0.188 | 4.78 | ||||||||||

| 18 | 0.165 | 4.19 | 0.188 | 4.78 | ||||||||||

| 20 | 0.188 | 4.78 | 0.218 | 5.54 | ||||||||||

| 22 | 0.188 | 4.78 | 0.218 | 5.54 | ||||||||||

| 24 | 0.218 | 5.54 | 0.25 | 6.35 | ||||||||||

| 30 | 0.25 | 6.35 | 0.312 | 7.92 | ||||||||||

| End of pipe end | ||||||||||||||

| Plain Ends (PE) | The PE pipes will generally be used for the smaller diameters pipe systems and in combination with Slip On flanges and Socket Weld fittings and flanges. | |||||||||||||

| Threaded Ends (TE) | The TE implementation speaks for itself, this performance will generally used for small diameters pipe systems, and the connections will be made with threaded flanges and threaded fittings. | |||||||||||||

| Beveled Ends (BE) | The BE implementation is applied to all diameters of buttweld flanges or buttweld fittings, and will be directly welded (with a small gap 3-4 mm) to each other or to the pipe. Ends are mostly be beveled to angle 30° (+ 5° / -0°) with a root face of 1.6 mm (± 0.8 mm). | |||||||||||||

| Grooved ends | (example Victaulic pipes): these are pipes that allow a quick connection, used for non-critical applications | |||||||||||||

| Threaded and coupled ends |

(T&C), generally used for gas distribution, Threaded connections are the most common pipe fittings used in oil and gas transportation systems. Due to external vibrations, cyclic loads, and pollution, the fitting parts may start getting loose, which could result in pipeline leaks and other environmental disasters. It is of great significance to develop a reliable technique that could provide… |

|||||||||||||

| Type end : Plain Ends / Beveled Ends: Tubes – Pipe | ||||||||||||||

|

• Bevel End (BE) • Bevel Both Ends (BBE) • Bevel Large End (BLE) • Bevel One End (BOE) • Bevel Small End (BSE) • Bevel for Welding (BFW) • Buttweld End (BE) |

• End of Pipe (EOP) • Flange One End (FOE) • Plain End (PE) • Plain Both Ends (PBE) • Plain One End (POE) • Thread End (TE) • Thread Both Ends (TBE) |

• Thread Large End (TLE) • Thread One End (TOE) • Thread Small End (TSE) • Threads Only (TO) • Threads per Inch (TP I) |

||||||||||||

| Plastic End Caps for Tubing and Pipe Ends | ||||||||||||||

| Pipe End Caps | Pipe End Plugs | Threaded Pipe Caps | Threaded Pipe Plugs | |||||||||||

| Standard: Pipe of Tube | ||||||||||||||

| The American Society Of Mechanical Engineers | American National Standards Institute | |||||||||||||

| ASME B36.19M | ANSI B36.19M | |||||||||||||

| ASME B36.10M | ANSI B36.10M | |||||||||||||

| Product related keywords | |

| Ferritic/Austenitic (Duplex) Stainless Steel Electric Fusion Welded Pipe A928 Grade S32750 | |

| Electric Fusion Welded Pipe | EFW Pipe |

| Electric Fusion Welded Pipe A928 Grade S32750 | FFW Pipe, A928 Grade S32750 |

| Duplex Stainless Steel, Electric Fusion Welded Pipe, A928 Grade S32750 | Duplex Stainless Steel, EFW Pipe ,A928 Grade S32750 |

| Ferritic Stainless Steel, Electric Fusion Welded Pipe, A928 Grade S32750 | Ferritic Stainless Steel, EFW Pipe ,A928 Grade S32750 |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 5 | Electric Fusion Welded Pipe A928 Grade S32750, SCH 5S |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 10 | Electric Fusion Welded Pipe A928 Grade S32750, SCH 10S |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 20 | Electric Fusion Welded Pipe A928 Grade S32750, SCH 30 |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH STD | Electric Fusion Welded Pipe A928 Grade S32750, SCH 40S |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 60 | Electric Fusion Welded Pipe A928 Grade S32750, SCH XS |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 80 | Electric Fusion Welded Pipe A928 Grade S32750, SCH 80S |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 100 | Electric Fusion Welded Pipe A928 Grade S32750, SCH 120 |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH 160 | Electric Fusion Welded Pipe A928 Grade S32750, SCH XXS |

| Electric Fusion Welded Pipe A928 Grade S32750, SCH XX.H | |

| Dimensions of Steel Pipes ASME B36.10 and B36.19 | ||||||

| Ferritic/Austenitic (Duplex) Stainless Steel Electric Fusion Welded Pipe A928 Grade S32750 | ||||||

| 1/2 inches to 2 inches | ||||||

| NPS | 1/2" | 3/4" | 1" | 1¼" | 1½" | 2" |

| OD | 21.3 | 26.7 | 33.4 | 42.2 | 48.3 | 60.3 |

| Wall Thickness | ||||||

| Sch 5 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 |

| Sch 5S | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 |

| Sch 10 | 2.11 | 2.11 | 2.77 | 2.77 | 2.77 | 2.77 |

| Sch 10S | 2.11 | 2.11 | 2.77 | 2.77 | 2.77 | 2.77 |

| Sch 20 | – | … | – | … | – | … |

| Sch 30 | 2.41 | 2.41 | 2.90 | 2.97 | 3.18 | 3.18 |

| STD | 2.77 | 2.87 | 3.38 | 3.56 | 3.68 | 3.91 |

| Sch 40 | 2.77 | 2.87 | 3.38 | 3.56 | 3.68 | 3.91 |

| Sch 40S | 2.77 | 2.87 | 3.38 | 3.56 | 3.68 | 3.91 |

| Sch 60 | – | … | – | … | – | … |

| XS | 3.73 | 3.91 | 4.55 | 4.85 | 5.08 | 5.54 |

| Sch 80 | 3.73 | 3.91 | 4.55 | 4.85 | 5.08 | 5.54 |

| Sch 80S | 3.73 | 3.91 | 4.55 | 4.85 | 5.08 | 5.54 |

| Sch 100 | – | … | – | … | – | … |

| Sch 120 | – | … | – | … | – | … |

| Sch 140 | – | … | – | … | – | … |

| XXS | 7.47 | 7.82 | 9.09 | 9.70 | 10.15 | 11.07 |

| Sch 160 | 4.78 | 5.56 | 6.35 | 6.35 | 7.14 | 8.74 |

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 2 1/2 inches to 5 inches | ||||||

| NPS | 2½" | 3" | 3½" | 4" | 5" | |

| OD | 73 | 88.9 | 101.6 | 114.3 | 141.3 | |

| Wall Thickness | ||||||

| Sch 5 | 2.11 | 2.11 | 2.11 | 2.11 | 2.77 | |

| Sch 5S | 2.11 | 2.11 | 2.11 | 2.11 | 2.77 | |

| Sch 10 | 3.05 | 3.05 | 3.05 | 3.05 | 3.40 | |

| Sch 10S | 3.05 | 3.05 | 3.05 | 3.05 | 3.40 | |

| Sch 20 | … | … | ||||

| Sch 30 | 4.78 | 4.78 | 4.78 | 4.78 | … | |

| STD | 5.16 | 5.49 | 5.74 | 6.02 | 6.55 | |

| Sch 40 | 5.16 | 5.49 | 5.74 | 6.02 | 6.55 | |

| Sch 40S | 5.16 | 5.49 | 5.74 | 6.02 | 6.55 | |

| Sch 60 | … | … | ||||

| XS | 7.01 | 7.62 | 8.08 | 8.56 | 9.53 | |

| Sch 80 | 7.01 | 7.62 | 8.08 | 8.56 | 9.53 | |

| Sch 80S | 7.01 | 7.62 | 8.08 | 8.56 | 9.53 | |

| Sch 100 | … | … | ||||

| Sch 120 | … | 11.13 | 12.7 | |||

| Sch 140 | … | … | ||||

| XXS | 14.02 | 15.24 | 17.12 | 19.05 | ||

| Sch 160 | 9.53 | 11.13 | 13.49 | 15.88 | ||

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 6 inches to 14 inches | ||||||

| NPS | 6" | 8" | 10" | 12" | 14" | |

| OD | 168.3 | 219 | 273 | 323.9 | 355.6 | |

| Wall Thickness | ||||||

| Sch 5 | 2.77 | 2.77 | 3.40 | 3.96 | 3.96 | |

| Sch 5S | 2.77 | 2.77 | 3.40 | 3.96 | 3.96 | |

| Sch 10 | 3.40 | 3.76 | 4.19 | 4.57 | 6.35 | |

| Sch 10S | 3.40 | 3.76 | 4.19 | 4.57 | 4.78 | |

| Sch 20 | 6.35 | 6.35 | 6.35 | 7.92 | ||

| Sch 30 | 7.04 | 7.80 | 8.38 | 9.53 | ||

| STD | 7.11 | 8.18 | 9.27 | 9.53 | 9.53 | |

| Sch 40 | 7.11 | 8.18 | 9.27 | 10.31 | 11.13 | |

| Sch 40S | 7.11 | 8.18 | 9.27 | 9.53 | 9.53 | |

| Sch 60 | 10.31 | 12.70 | 14.27 | 15.06 | ||

| XS | 10.97 | 12.70 | 12.70 | 12.70 | 12.70 | |

| Sch 80 | 10.97 | 12.70 | 15.09 | 17.48 | 19.05 | |

| Sch 80S | 10.97 | 12.70 | 12.70 | 12.70 | 12.70 | |

| Sch 100 | 15.09 | 18.26 | 21.44 | 23.83 | ||

| Sch 120 | 14.27 | 18.26 | 21.44 | 25.40 | 27.79 | |

| Sch 140 | 20.62 | 25.40 | 28.58 | 31.75 | ||

| XXS | 21.95 | 22.23 | 25.40 | 25.40 | ||

| Sch 160 | 18.26 | 23.01 | 28.58 | 33.32 | 35.71 | |

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 16 inches to 24 inches | ||||||

| NPS | 16" | 18" | 20" | 22" | 24" | |

| OD | 406.04 | 457.2 | 508 | 558.8 | 609.6 | |

| Wall Thickness | ||||||

| Sch 5 | 4.19 | 4.19 | 4.78 | 4.78 | 5.54 | |

| Sch 5S | 4.19 | 4.19 | 4.78 | 4.78 | 5.54 | |

| Sch 10 | 6.35 | 6.35 | 6.35 | 6.35 | 6.35 | |

| Sch 10S | 4.78 | 4.78 | 5.54 | 5.54 | 6.35 | |

| Sch 20 | 7.92 | 7.92 | 9.53 | 9.53 | 9.53 | |

| Sch 30 | 9.53 | 11.13 | 12.70 | 12.70 | 14.27 | |

| STD | 9.53 | 9.53 | 9.53 | 9.53 | 9.53 | |

| Sch 40 | 12.70 | 14.27 | 15.09 | … | 17.48 | |

| Sch 40S | 9.53 | 9.53 | 9.53 | … | 9.53 | |

| Sch 60 | 16.66 | 19.05 | 20.62 | 22.23 | 24.61 | |

| XS | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | |

| Sch 80 | 21.44 | 23.83 | 26.19 | 28.58 | 30.96 | |

| Sch 80S | 12.70 | 12.70 | 12.70 | … | 12.70 | |

| Sch 100 | 26.19 | 29.36 | 32.54 | 34.93 | 38.89 | |

| Sch 120 | 30.96 | 34.93 | 38.10 | 41.28 | 46.02 | |

| Sch 140 | 36.53 | 39.67 | 44.45 | 47.63 | 52.37 | |

| XXS | … | … | ||||

| Sch 160 | 40.49 | 45.24 | 50.01 | 53.98 | 59.54 | |

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 26 inches to 48 inches | ||||||

| 26" > 48" | Wall Thickness and Weight | |||||

| NPS | OD | 5 | 5S | 10 | ||

| 26 | 660 | wt | 7.92 | |||

| kg/m | 127.36 | |||||

| 28 | 711 | wt | 7.92 | |||

| kg/m | 137.32 | |||||

| 30 | 762 | wt | 6.35 | 6.35 | 7.92 | |

| kg/m | 118.34 | 118.31 | 147.29 | |||

| 32 | 813 | wt | 7.92 | |||

| kg/m | 157.25 | |||||

| 34 | 864 | wt | 7.92 | |||

| kg/m | 167.21 | |||||

| 36 | 914 | wt | 7.92 | |||

| kg/m | 176.97 | |||||

| 38 | 965 | wt | ||||

| kg/m | ||||||

| 40 | 1016 | wt | ||||

| kg/m | ||||||

| 42 | 1067 | wt | ||||

| kg/m | ||||||

| 44 | 1118 | wt | ||||

| kg/m | ||||||

| 46 | 1168 | wt | ||||

| kg/m | ||||||

| 48 | 1219 | wt | ||||

| kg/m | ||||||

| 26 – 48 | Wall Thickness and Weight | |||||

| NPS | OD | 10S | 20 | 30 | ||

| 26 | 660 | wt | 12.70 | |||

| kg/m | 202.74 | |||||

| 28 | 711 | wt | 12.70 | 15.88 | ||

| kg/m | 218.71 | 272.23 | ||||

| 30 | 762 | wt | 7.92 | 12.70 | 15.88 | |

| kg/m | 132.91 | 234.68 | 292.20 | |||

| 32 | 813 | wt | 12.70 | 15.88 | ||

| kg/m | 250.65 | 312.17 | ||||

| 34 | 864 | wt | 12.70 | 15.88 | ||

| kg/m | 266.63 | 332.14 | ||||

| 36 | 914 | wt | 12.70 | 15.88 | ||

| kg/m | 282.29 | 351.73 | ||||

| 38 | 965 | wt | ||||

| kg/m | ||||||

| 40 | 1016 | wt | ||||

| kg/m | ||||||

| 42 | 1067 | wt | ||||

| kg/m | ||||||

| 44 | 1118 | wt | ||||

| kg/m | ||||||

| 46 | 1168 | wt | ||||

| kg/m | ||||||

| 48 | 1219 | wt | ||||

| kg/m | ||||||

| 26 – 48 | Wall Thickness and Weight | |||||

| NPS | OD | STD | 40 | XS | ||

| 26 | 660 | wt | 9.53 | 12.70 | ||

| kg/m | 152.88 | 202.74 | ||||

| 28 | 711 | wt | 9.53 | 12.70 | ||

| kg/m | 164.86 | 218.71 | ||||

| 30 | 762 | wt | 9.53 | 12.70 | ||

| kg/m | 176.85 | 234.68 | ||||

| 32 | 813 | wt | 9.53 | 17.48 | 12.70 | |

| kg/m | 188.83 | 342.94 | 250.65 | |||

| 34 | 864 | wt | 9.53 | 17.48 | 12.70 | |

| kg/m | 200.82 | 364.92 | 266.63 | |||

| 36 | 914 | wt | 9.53 | 19.05 | 12.70 | |

| kg/m | 212.57 | 420.45 | 282.29 | |||

| 38 | 965 | wt | 9.53 | 12.70 | ||

| kg/m | 224.56 | 298.26 | ||||

| 40 | 1016 | wt | 9.53 | 12.70 | ||

| kg/m | 236.54 | 314.23 | ||||

| 42 | 1067 | wt | 9.53 | 12.70 | ||

| kg/m | 248.53 | 330.21 | ||||

| 44 | 1118 | wt | 9.53 | 12.70 | ||

| kg/m | 260.52 | 346.18 | ||||

| 46 | 1168 | wt | 9.53 | 12.70 | ||

| kg/m | 272.70 | 361.84 | ||||

| 48 | 1219 | wt | 9.53 | 12.70 | ||

| kg/m | 284.25 | 377.81 | ||||

| NPS = Nominal Pipe Size | ||||||

| O.D. = Outside Diameter | ||||||

| WT = Walltickness | ||||||

| KG/M = Kilogram per meter | ||||||

| Dimensions are in millimeters unless otherwise indicated | ||||||

| Weights are in kilograms p/meter and approximately given | ||||||

Mr. Thi

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 982 384 688

Hotline/ Zalo/ Wechat:

+84 982 384 688

|

Ms. Hoa

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 982 803 586

Hotline/ Zalo/ Wechat:

+84 982 803 586

|

Ms. Phương

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 341

Hotline/ Zalo/ Wechat:

+84 971 567 341

|

Ms. Trinh

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 943

Hotline/ Zalo/ Wechat:

+84 971 567 943

|

Ms. Trân

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 954

Hotline/ Zalo/ Wechat:

+84 971 567 954

|

Home

Home