-

+84 982 384 688 - Mr. Thi | +84 982 803 586- Ms. Hoa

-

theptangiabao@gmail.com

-

Thứ 2 - Thứ 7 | 07:30 - 17:00

Forged Swage Nipple A105 Threaded #3000 - #6000

Product info

Product info

| Supplier: | TAN GIA BAO DV TRADING INVESTMENT CO.,LTD |

| Address: | 137 National Highway 1A, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Viet Nam |

| Phone: | +84 982 384 688 |

| Email: | theptangiabao@gmail.com |

| Website: | https://theptangiabao.com/ |

| Insurance: | 12 months |

| Status: | New 100% |

| Origin: | China, Korea, Malaysia, Thailand, Japan, EU, G7 |

Swage nipple is a pressure fitting used to connect two pipes of different sizes. Usually it is a 4-stage reducing connection. That means the reducing cone has a reduced size of 2" x 1.1/2", 2" x 1.1/4", 2" x 1", and 2" x 3/4". This type of product has an NPT male thread connection between the 2 ends.

Tan Gia Bao DV Trading Investment Co., LTD

Providing a full range of steel pipe accessories, welding accessories and industrial supplies according to customer needs

Standard: ASME B16.11

Material: ASTM A105/A105N (SA105/SA105N) steel; Stainless steel: F304/304L, F316/316L

Size: 1/2'' – 4'' (DN15-DN100)

Pressure/Class: 3000#, 6000#

Connection type: Socket welded

Origin: China

Nominal Pipe Size (NPS)

|

Outside Diameter

|

End To End “A”

|

Wall Thickness

|

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Large End D1

|

Small End D2

|

T1

|

T2

|

||||||||

Sch40 (STD)

|

Sch80 (XS)

|

Sch160

|

XXS

|

Sch40 (STD)

|

Sch80 (XS)

|

Sch160

|

XXS

|

||||

1/4”x1/8”

|

13.7

|

10.3

|

57

|

2.2

|

3.0

|

3.7

|

6.1

|

1.7

|

2.4

|

|

|

3/8”x1/8”

|

17.1

|

10.3

|

64

|

2.3

|

3.2

|

4.0

|

6.4

|

1.7

|

2.4

|

|

|

3/8”x1/4”

|

17.1

|

13.7

|

64

|

2.3

|

3.2

|

4.0

|

6.4

|

2.2

|

3.0

|

|

|

1/2”x1/8”

|

21.3

|

10.3

|

70

|

2.8

|

3.7

|

4.8

|

7.5

|

1.7

|

2.4

|

|

|

1/2”x1/4”

|

21.3

|

13.7

|

70

|

2.8

|

3.7

|

4.8

|

7.5

|

2.2

|

3.0

|

|

|

1/2”x3/8”

|

21.3

|

17.1

|

70

|

2.8

|

3.7

|

4.8

|

7.5

|

2.3

|

3.2

|

|

|

3/4”x1/8”

|

26.7

|

10.3

|

76

|

2.9

|

3.9

|

5.6

|

7.8

|

1.7

|

2.4

|

|

|

3/4’x1/4”

|

26.7

|

13.7

|

76

|

2.9

|

3.9

|

5.6

|

7.8

|

2.2

|

3.0

|

|

|

3/4”x3/8”

|

26.7

|

17.1

|

76

|

2.9

|

3.9

|

5.6

|

7.8

|

2.3

|

3.2

|

|

|

3/4”x1/2”

|

26.7

|

21.3

|

76

|

2.9

|

3.9

|

5.6

|

7.8

|

2.8

|

3.7

|

4.8

|

7.5

|

1”x1/8”

|

33.4

|

10.3

|

89

|

3.4

|

4.5

|

6.4

|

9.1

|

1.7

|

2.4

|

|

|

1”x1/4”

|

33.4

|

13.7

|

89

|

3.4

|

4.5

|

6.4

|

9.1

|

2.2

|

3.0

|

|

|

1”x3/8”

|

33.4

|

17.1

|

89

|

3.4

|

4.5

|

6.4

|

9.1

|

2.3

|

3.2

|

|

|

1”x1/2”

|

33.4

|

21.3

|

89

|

3.4

|

4.5

|

6.4

|

9.1

|

2.8

|

3.7

|

4.8

|

7.5

|

1”x3/4”

|

33.4

|

26.7

|

89

|

3.4

|

4.5

|

6.4

|

9.1

|

2.9

|

3.9

|

5.6

|

7.8

|

1-1/4”x1/8”

|

42.2

|

10.3

|

102

|

3.6

|

4.9

|

6.4

|

9.7

|

1.7

|

2.4

|

|

|

1-1/4”x1/4”

|

42.2

|

13.7

|

102

|

3.6

|

4.9

|

6.4

|

9.7

|

2.2

|

3.0

|

|

|

1-1/4”x3/8”

|

42.2

|

17.1

|

102

|

3.6

|

4.9

|

6.4

|

9.7

|

2.3

|

3.2

|

|

|

1-1/4”x1/2”

|

42.2

|

21.3

|

102

|

3.6

|

4.9

|

6.4

|

9.7

|

2.8

|

3.7

|

4.8

|

7.5

|

1-1/4”x3/4”

|

42.2

|

26.7

|

102

|

3.6

|

4.9

|

6.4

|

9.7

|

2.9

|

3.9

|

5.6

|

7.8

|

1-1/4”x1”

|

42.2

|

33.4

|

102

|

3.6

|

4.9

|

6.4

|

9.7

|

3.4

|

4.5

|

6.4

|

9.1

|

1-1/2”x1/8”

|

48.3

|

10.3

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

1.7

|

2.4

|

|

|

1-1/2”x1/4”

|

48.3

|

13.7

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

2.2

|

3.0

|

|

|

1-1/2”x3/8”

|

48.3

|

17.1

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

2.3

|

3.2

|

|

|

1-1/2”x1/2”

|

48.3

|

21.3

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

2.8

|

3.7

|

4.8

|

7.5

|

1-1/2”x3/4”

|

48.3

|

26.7

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

2.9

|

3.9

|

5.6

|

7.8

|

1-1/2”x1”

|

48.3

|

33.4

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

3.4

|

4.5

|

6.4

|

9.1

|

1-1/2”x1-1/4”

|

48.3

|

42.2

|

114

|

3.7

|

5.1

|

7.1

|

10.2

|

3.6

|

4.9

|

6.4

|

9.7

|

2”x1/8”

|

60.3

|

10.3

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

1.7

|

2.4

|

|

|

2”x1/4”

|

60.3

|

13.7

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

2.2

|

3.0

|

|

|

2”x3/8”

|

60.3

|

17.1

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

2.3

|

3.2

|

|

|

2”x1/2”

|

60.3

|

21.3

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

2.8

|

3.7

|

4.8

|

7.5

|

2”x3/4”

|

60.3

|

26.7

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

2.9

|

3.9

|

5.6

|

7.8

|

2”x1”

|

60.3

|

33.4

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

3.4

|

4.5

|

6.4

|

9.1

|

2”x1-1/4”

|

60.3

|

42.2

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

3.6

|

4.9

|

6.4

|

9.7

|

2”x1-1/2”

|

60.3

|

48.3

|

165

|

3.9

|

5.5

|

8.7

|

11.1

|

3.7

|

5.1

|

7.1

|

10.2

|

2-1/2”x1/8”

|

73.0

|

10.3

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

1.7

|

2.4

|

|

|

2-1/2”x1/4”

|

73.0

|

13.7

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

2.2

|

3.0

|

|

|

2-1/2”x3/8”

|

73.0

|

17.1

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

2.3

|

3.2

|

|

|

2-1/2”x1/2”

|

73.0

|

21.3

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

2.8

|

3.7

|

4.8

|

7.5

|

2-1/2”x3/4”

|

73.0

|

26.7

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

2.9

|

3.9

|

5.6

|

7.8

|

2-1/2”x1”

|

73.0

|

33.4

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

3.4

|

4.5

|

6.4

|

9.1

|

2-1/2”x1-1/4”

|

73.0

|

42.2

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

3.6

|

4.9

|

6.4

|

9.7

|

2-1/2”x1-1/2”

|

73.0

|

48.3

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

3.7

|

5.1

|

7.1

|

10.2

|

2-1/2”x2”

|

73.0

|

60.3

|

178

|

5.2

|

7.0

|

9.5

|

14.0

|

3.9

|

5.5

|

8.7

|

11.1

|

3”x1/8”

|

88.9

|

10.3

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

1.7

|

2.4

|

3.2

|

4.8

|

3”x1/4”

|

88.9

|

13.7

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

2.2

|

3.0

|

3.7

|

6.1

|

3”x3/8”

|

88.9

|

17.1

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

2.3

|

3.2

|

4.0

|

6.4

|

3”x1/2”

|

88.9

|

21.3

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

2.8

|

3.7

|

4.8

|

7.5

|

3”x3/4”

|

88.9

|

26.7

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

2.9

|

3.9

|

5.6

|

7.8

|

3”x1”

|

88.9

|

33.4

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

3.4

|

4.5

|

6.4

|

9.1

|

3”x1-1/4”

|

88.9

|

42.2

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

3.6

|

4.9

|

6.4

|

9.7

|

3”x1-1/2”

|

88.9

|

48.3

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

3.7

|

5.1

|

7.1

|

10.2

|

3”x2”

|

88.9

|

60.3

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

3.9

|

5.5

|

8.7

|

11.1

|

3”x2-1/2”

|

88.9

|

73.0

|

203

|

5.5

|

7.6

|

11.1

|

15.2

|

5.2

|

7.0

|

9.5

|

14.0

|

3-1/2”x1/8”

|

101.6

|

10.3

|

203

|

5.7

|

8.1

|

|

|

1.7

|

2.4

|

|

|

3-1/2”x1/4”

|

101.6

|

13.7

|

203

|

5.7

|

8.1

|

|

|

2.2

|

3.0

|

|

|

3-1/2”x3/8”

|

101.6

|

17.1

|

203

|

5.7

|

8.1

|

|

|

2.3

|

3.2

|

|

|

3-1/2”x1/2”

|

101.6

|

21.3

|

203

|

5.7

|

8.1

|

|

|

2.8

|

3.7

|

4.8

|

7.5

|

3-1/2”x3/4”

|

101.6

|

26.7

|

203

|

5.7

|

8.1

|

|

|

2.9

|

3.9

|

5.6

|

7.8

|

3-1/2”x1”

|

101.6

|

33.4

|

203

|

5.7

|

8.1

|

|

|

3.4

|

4.5

|

6.4

|

9.1

|

3-1/2”x1-1/4”

|

101.6

|

42.2

|

203

|

5.7

|

8.1

|

|

|

3.6

|

4.9

|

6.4

|

9.7

|

3-1/2”x1-1/2”

|

101.6

|

48.3

|

203

|

5.7

|

8.1

|

|

|

3.7

|

5.1

|

7.1

|

10.2

|

3-1/2”x2”

|

101.6

|

60.3

|

203

|

5.7

|

8.1

|

|

|

3.9

|

5.5

|

8.7

|

11.1

|

3-1/2”x2-1/2”

|

101.6

|

73.0

|

203

|

5.7

|

8.1

|

|

|

5.2

|

7.0

|

9.5

|

14.0

|

3-1/2”x3”

|

101.6

|

88.9

|

203

|

5.7

|

8.1

|

|

|

5.5

|

7.6

|

11.1

|

15.2

|

4”x1/4”

|

114.3

|

13.7

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

2.2

|

3.0

|

|

|

4”x3/8”

|

114.3

|

17.1

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

2.3

|

3.2

|

|

|

4”x1/2”

|

114.3

|

21.3

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

2.8

|

3.7

|

4.8

|

7.5

|

4”x3/4”

|

114.3

|

26.7

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

2.9

|

3.9

|

5.6

|

7.8

|

4”x1”

|

114.3

|

33.4

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

3.4

|

4.5

|

6.4

|

9.1

|

4”x1-1/4”

|

114.3

|

42.2

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

3.6

|

4.9

|

6.4

|

9.7

|

4”x1-1/2”

|

114.3

|

48.3

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

3.7

|

5.1

|

7.1

|

10.2

|

4”x2”

|

114.3

|

60.3

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

3.9

|

5.5

|

8.7

|

11.1

|

4”x2-1/2”

|

114.3

|

73.0

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

5.2

|

7.0

|

9.5

|

14.0

|

4”x3”

|

114.3

|

88.9

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

5.5

|

7.6

|

11.1

|

15.2

|

4”x3-1/2”

|

114.3

|

101.6

|

229

|

6.0

|

8.6

|

13.5

|

17.1

|

5.7

|

8.1

|

|

|

-

Dimensions in Millimeters.

-

Wall Thickness:T1 & T2 in accordance with ASME B36.10M

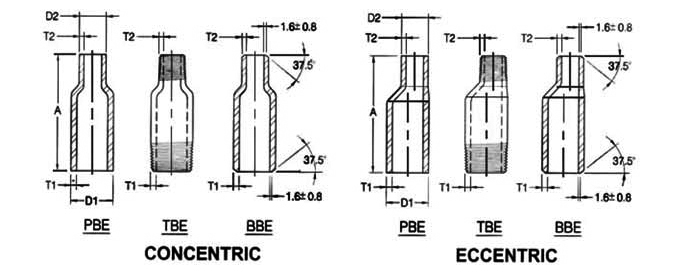

PBE: Plain Both Ends

|

BBE: Bevel Both Ends

|

TBE: Thread Both Ends

|

PSE: Plain Small End

|

BSE: Bevel Small End

|

TSE: Thread Small End

|

PLE: Plain Large End

|

BLE: Bevel Large End

|

TLE: Thread Large End

|

Dimensional Tolerance of Swaged Nipple:

Nominal Pipe Size (inch)

|

Overall Length (mm)

|

Outside diameter at end

|

Wall Thickness (prior to threading or grooving)

|

|

|---|---|---|---|---|

Square Cut Ends (mm)

|

Other End Connection (mm)

|

|||

1/8” to 3/8”

|

± 1.5

|

+ 0.40

|

± 0.80

|

Not less than 87.5% of nominal wall thickness

|

1/2” to 1-1/2”

|

± 1.5

|

+ 0.40

|

+ 1.50

|

|

2” to 2-1/2”

|

± 3.0

|

± 0.80

|

+ 1.50

|

|

3” to 4”

|

± 3.0

|

± 0.80

|

± 1.50

|

|

Seamless Swage Nipples:

I.D. or Nominal Size

|

Outside Diameter

|

Length

|

||

|---|---|---|---|---|

NU

|

EUE

|

NU

|

EUE

|

|

1/8

|

—

|

—

|

—

|

—

|

1/4

|

.540

|

—

|

2 1/4

|

—

|

3/8

|

.675

|

—

|

2 1/2

|

—

|

1/2

|

.840

|

—

|

2 3/4

|

—

|

3/4

|

1.050

|

—

|

3

|

—

|

1

|

1.315

|

1.469

|

3 1/2

|

4 1/2

|

1 1/4

|

1.660

|

1.812

|

4

|

6

|

I.D. or Nominal Size

|

Outside Diameter

|

Length

|

||

|---|---|---|---|---|

NU

|

EUE

|

NU

|

EUE

|

|

1 1/2

|

1.900

|

2.094

|

4 1/2

|

6

|

2

|

2.375

|

2.594

|

6 1/2

|

8

|

2 1/2

|

2.875

|

3.094

|

7

|

8

|

3

|

3.500

|

3.750

|

8

|

8

|

3 1/2

|

4.000

|

4.250

|

8

|

8

|

4

|

4.500

|

4.750

|

9

|

9

|

Tan Gia Bao DV Trading Investment Co., LTD

Providing a full range of steel pipe accessories, welding accessories and industrial supplies according to customer needs

Their typical applications can include:

Applied in water supply and drainage systems of industrial parks, production areas, residential areas,…

Used widely in fire protection systems.

Used in oil pipelines, gas pipelines, gas pipelines, etc.

Shipbuilding industry.

Used in the chemical industry, substances that are corrosive, oxidizing, etc.

Food production industry, food, pharmaceuticals,…

Applications in textile, dyeing,…

Cement, paper, pulp manufacturing industry,…

Fertilizer factory.

Mr. Thi

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 982 384 688

Hotline/ Zalo/ Wechat:

+84 982 384 688

|

Ms. Hoa

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 982 803 586

Hotline/ Zalo/ Wechat:

+84 982 803 586

|

Ms. Phương

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 341

Hotline/ Zalo/ Wechat:

+84 971 567 341

|

Ms. Trinh

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 943

Hotline/ Zalo/ Wechat:

+84 971 567 943

|

Ms. Trân

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 954

Hotline/ Zalo/ Wechat:

+84 971 567 954

|

Home

Home