-

+84 982 384 688 - Mr. Thi | +84 982 803 586- Ms. Hoa

-

theptangiabao@gmail.com

-

Thứ 2 - Thứ 7 | 07:30 - 17:00

Seamless Pipe A106 Grade C

Product info

Product info

| Supplier: | Tapgroup internation.,JSC |

| Address: | Số 32 Lô N4D, đường X2A, Yên Sở, Hoàng Mai, Hà Nội |

| Phone: | 0084 933 86 77 86 |

| Email: | info@tapgroup.vn |

| Website: | https://supplier-pipe-tube-ongthep.com |

| Insurance: | 12 tháng |

| Status: | Mới 100% |

| Origin: | China, Korea, Malaysia, Thailand, Japan, EU, G7 |

| Name: | Seamless Pipe A106 Grade C | ||||||||||||||||||||||

| Seamless Carbon Steel Pipe for High-Temperature Pipe A106 Grade C | |||||||||||||||||||||||

| Type of Pipe | Seamless Pipe A106 Grade C | Pipe A106 Grade C, SMLS | |||||||||||||||||||||

| Seamless Pipe A106 Grade C, Galvanized | Pipe A106 Grade C, SMLS, Galvanized | ||||||||||||||||||||||

| Seamless Pipe A106 Grade C, Zinc coated | Pipe A106 Grade C, SMLS, Zinc coated | ||||||||||||||||||||||

| Seamless Pipe A106 Grade C, Pickled and oiled | Pipe A106 Grade C, SMLS, Pickled and oiled | ||||||||||||||||||||||

| Chemical Requirements | |||||||||||||||||||||||

| Element | Composition, % | ||||||||||||||||||||||

| Grade A | Grade B | Grade C | |||||||||||||||||||||

| Carbon, maxA | 0.25 | 0.30 | 0.35 | ||||||||||||||||||||

| Manganese | 0.27–0.93 | 0.29–1.06 | 0.29–1.06 | ||||||||||||||||||||

| Phosphorus, max | 0.035 | 0.035 | 0.035 | ||||||||||||||||||||

| Sulfur, max | 0.035 | 0.035 | 0.035 | ||||||||||||||||||||

| Silicon, min | 0.10 | 0.10 | 0.10 | ||||||||||||||||||||

| Chrome, maxB | 0.40 | 0.40 | 0.40 | ||||||||||||||||||||

| Copper, maxB | 0.40 | 0.40 | 0.40 | ||||||||||||||||||||

| Molybdenum, maxB | 0.15 | 0.15 | 0.15 | ||||||||||||||||||||

| Nickel, maxB | 0.40 | 0.40 | 0.40 | ||||||||||||||||||||

| Vanadium, maxB | 0.08 | 0.08 | 0.08 | ||||||||||||||||||||

|

For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.35 %. B These five elements combined shall not exceed 1 %. |

|||||||||||||||||||||||

|

Heat Treatment 5.1 Hot-finished pipe need not be heat treated. Cold-drawn pipe shall be heat treated after the final cold draw pass at a temperature of 1200°F (650°C) or higher. |

|||||||||||||||||||||||

| Tensile Requirements | |||||||||||||||||||||||

| Grade A(Explanatory Note 2) | Grade B | Grade C | |||||||||||||||||||||

| Tensile strength, min, psi (MPa) | 48 000 (330) | 60 000 (415) | 70 000 (485) | ||||||||||||||||||||

| Yield strength, min, psi (MPa) | 30 000 (205) | 35 000 (240 | 40 000 (275) | ||||||||||||||||||||

| Elongation in 2 in. or 50 mm, min, %: | Longitu-dinal | Transverse | Longitu-dinal | Transverse | Longitu-dinal | Transverse | |||||||||||||||||

| Basic minimum elongation transverse strip tests, and for all small sizes tested in full section | 35 | 25 | 30 | 16.5 | 30 | 16.5 | |||||||||||||||||

| When standard round 2-in. or 50-mm gage length test specimen is used | 28 | 20 | 22 | 12 | 20 | 12 | |||||||||||||||||

| For longitudinal strip tests | A,B | A,B | A,B | ||||||||||||||||||||

| For transverse strip tests, a deduction for each 1⁄32-in. (0.8-mm) decrease in wall thickness below 5⁄16 in. (7.9 mm) from the basic minimum elongation of the following percentage shall be made | 1.25C | 1.00C | 1.00C | ||||||||||||||||||||

| AThe minimum elogation in 2 in. (50.8 mm) shall be determined by the following equation: | |||||||||||||||||||||||

| e = 625 000A0.2 / U 0.9 | |||||||||||||||||||||||

| where: | |||||||||||||||||||||||

| e = minimum elongation in 2 in. (50.8 mm), %, rounded to the nearest 0.5 %, | |||||||||||||||||||||||

| A = cross-sectional area of the tension test specimen, in.2, based on specified outside diameter or nominal specimen width and specified wall thickness rounded to the nearest 0.01 in. 2(if the area thus caluclated is greater than the value 0.75 in.2 shall be used), and | |||||||||||||||||||||||

| U = specified tensile strength, psi. | |||||||||||||||||||||||

| B See Table 4 for minimum elongation values for various size tension specimens and grades. | |||||||||||||||||||||||

| C Table 3 gives the computed minimum values: | |||||||||||||||||||||||

| Computed Transverse ElongationA | |||||||||||||||||||||||

| Wall Thickness | Elongation in 2 in. or 50 mm, min, % | ||||||||||||||||||||||

| in | mm | Grade A, Transverse | Grade B and C, Transverse | ||||||||||||||||||||

| 5/16(0.312) | 7.9 | 25.00 | 16.50 | ||||||||||||||||||||

| 9/32(0.281) | 7.1 | 23.75 | 15.50 | ||||||||||||||||||||

| 1/4(0.250) | 6.4 | 22.5 | 14.50 | ||||||||||||||||||||

| This table gives the computed minimum elongation values for each 1⁄32-in. (0.8-mm) decrease in wall thickness. Where the wall thickness lies between two values shown above, the minimum elongation value is determined by the following equation: | |||||||||||||||||||||||

| Grade | Direction of Test | Equation | |||||||||||||||||||||

| A | Transverse | E = 40t + 12.50 | |||||||||||||||||||||

| B and C | Transverse | E = 32t + 6.50 | |||||||||||||||||||||

| where: | |||||||||||||||||||||||

| E = elongation in 2 in. or 50 mm, %, and | |||||||||||||||||||||||

| t = actual thickness of specimen, in. | |||||||||||||||||||||||

| Elongation Values | |||||||||||||||||||||||

| Tension Test Specimen Wall Thickness, in.B | Elongation in 2 in. min., Specified Tensile Strength, psi | ||||||||||||||||||||||

| Grade A | Grade B | Grade C | |||||||||||||||||||||

| Area, in.2A | 1⁄2in. Specimen | 3/4in. Specimen | 1in. Specimen | 1 1⁄2 in. Specimen | 48,0000 | 60,000 | 70,000 | ||||||||||||||||

| ≥ 0.75 | ≥ 1.491 | ≥ 0.994 | ≥ 0.746 | ≥ 0.497 | 36.0 | 29.5 | 25.5 | ||||||||||||||||

| 0.74 | 1.470–1.490 | 0.980–0.993 | 0.735–0.745 | 0.490–0.496 | 36.0 | 29.5 | 25.5 | ||||||||||||||||

| 0.73 | 1.451–1.469 | 0.967–0.979 | 0.726–0.734 | 0.484–0.489 | 36.0 | 29.5 | 25.5 | ||||||||||||||||

| 0.72 | 1.430–1.450 | 0.954–0.966 | 0.715–0.725 | 0.477–0.483 | 36.0 | 29.5 | 25.5 | ||||||||||||||||

| 0.71 | 1.411–1.429 | 0.941–0.953 | 0.706–0.714 | 0.471–0.476 | 35.5 | 29.0 | 25.5 | ||||||||||||||||

| 0.70 | 1.390–1.410 | 0.927–0.940 | 0.695–0.705 | 0.464–0.470 | 35.5 | 29.0 | 25.5 | ||||||||||||||||

| 0.69 | 1.371–1.389 | 0.914–0.926 | 0.686–0.694 | 0.457–0.463 | 35.5 | 29.0 | 25.5 | ||||||||||||||||

| 0.68 | 1.350–1.370 | 0.900–0.913 | 0.675–0.685 | 0.450–0.456 | 35.5 | 29.0 | 25.0 | ||||||||||||||||

| 0.67 | 1.331–1.349 | 0.887–0.899 | 0.666–0.674 | 0.444–0.449 | 35.5 | 29.0 | 25.0 | ||||||||||||||||

| 0.66 | 1.310–1.330 | 0.874–0.886 | 0.655–0.665 | 0.437–0.443 | 35.0 | 29.0 | 25.0 | ||||||||||||||||

| 0.65 | 1.291–1.309 | 0.861–0.873 | 0.646–0.654 | 0.431–0.436 | 35.0 | 28.5 | 25.0 | ||||||||||||||||

| 0.64 | 1.270–1.290 | 0.847–0.860 | 0.635–0.645 | 0.424–0.430 | 35.0 | 28.5 | 25.0 | ||||||||||||||||

| 0.63 | 1.251–1.269 | 0.834–0.846 | 0.626–0.634 | 0.417–0.423 | 35.0 | 28.5 | 25.0 | ||||||||||||||||

| 0.62 | 1.230–1.250 | 0.820–0.833 | 0.615–0.625 | 0.410–0.416 | 35.0 | 28.5 | 25.0 | ||||||||||||||||

| 0.61 | 1.211–1.229 | 0.807–0.819 | 0.606–0.614 | 0.404–0.409 | 34.5 | 28.5 | 24.5 | ||||||||||||||||

| 0.60 | 1.190–1.210 | 0.794–0.806 | 0.595–0.605 | 0.397–0.403 | 34.5 | 28.5 | 24.5 | ||||||||||||||||

| 0.59 | 1.171–1.189 | 0.781–0.793 | 0.586–0.594 | 0.391–0.396 | 34.5 | 28.0 | 24.5 | ||||||||||||||||

| 0.58 | 1.150–1.170 | 0.767–0.780 | 0.575–0.585 | 0.384–0.390 | 34.5 | 28.0 | 24.5 | ||||||||||||||||

| 0.57 | 1.131–1.149 | 0.754–0.766 | 0.566–0.574 | 0.377–0.383 | 34.0 | 28.0 | 24.5 | ||||||||||||||||

| 0.56 | 1.110–1.130 | 0.740–0.753 | 0.555–0.565 | 0.370–0.376 | 34.0 | 28.0 | 24.5 | ||||||||||||||||

| Tension Test Specimen Wall Thickness, in.B | Elongation in 2 in. min., Specified Tensile Strength, psi | ||||||||||||||||||||||

| Grade A | Grade B | Grade C | |||||||||||||||||||||

| Area, in.2A | 1⁄2in. Specimen | 3/4in. Specimen | 1in. Specimen | 1 1⁄2 in. Specimen | 48,0000 | 60,000 | 70,000 | ||||||||||||||||

| 0.55 | 1.091–1.109 | 0.727–0.739 | 0.546–0.554 | 0.364–0.369 | 34.0 | 28.0 | 24.9 | ||||||||||||||||

| 0.54 | 1.070–1.090 | 0.714–0.726 | 0.535–0.545 | 0.357–0.363 | 34.0 | 27.5 | 24.0 | ||||||||||||||||

| 0.53 | 1.051–1.069 | 0.701–0.713 | 0.526–0.534 | 0.351–0.356 | 33.5 | 27.5 | 24.0 | ||||||||||||||||

| 0.52 | 1.030–1.050 | 0.687–0.700 | 0.515–0.525 | 0.344–0.350 | 33.5 | 27.5 | 24.0 | ||||||||||||||||

| 0.51 | 1.011–1.029 | 0.674–0.686 | 0.506–0.514 | 0.337–0.343 | 33.5 | 27.5 | 24.0 | ||||||||||||||||

| 0.50 | 0.990–1.010 | 0.660–0.673 | 0.495–0.505 | 0.330–0.336 | 33.5 | 27.0 | 23.5 | ||||||||||||||||

| 0.49 | 0.971–0.989 | 0.647–0.659 | 0.486–0.494 | 0.324–0.329 | 33.0 | 27.0 | 23.5 | ||||||||||||||||

| 0.48 | 0.950–0.970 | 0.634–0.646 | 0.475–0.485 | 0.317–0.323 | 33.0 | 27.0 | 23.5 | ||||||||||||||||

| 0.47 | 0.931–0.949 | 0.621–0.633 | 0.466–0.474 | 0.311–0.316 | 33.0 | 27.0 | 23.5 | ||||||||||||||||

| 0.46 | 0.910–0.930 | 0.607–0.620 | 0.455–0.465 | 0.304–0.310 | 33.0 | 27.0 | 23.5 | ||||||||||||||||

| 0.45 | 0.891–0.909 | 0.594–0.606 | 0.446–0.454 | 0.297–0.303 | 32.5 | 26.5 | 23.0 | ||||||||||||||||

| 0.44 | 0.870–0.890 | 0.580–0.593 | 0.435–0.445 | 0.290–0.296 | 32.5 | 26.5 | 23.0 | ||||||||||||||||

| 0.43 | 0.851–0.869 | 0.567–0.579 | 0.426–0.434 | 0.284–0.289 | 32.5 | 26.5 | 23.0 | ||||||||||||||||

| 0.42 | 0.830–0.850 | 0.554–0.566 | 0.415–0.425 | 0.277–0.283 | 32.0 | 26.5 | 23.0 | ||||||||||||||||

| 0.41 | 0.811–0.829 | 0.541–0.553 | 0.406–0.414 | 0.271–0.276 | 32.0 | 26.0 | 23.0 | ||||||||||||||||

| 0.40 | 0.790–0.810 | 0.527–0.540 | 0.395–0.405 | 0.264–0.270 | 32.0 | 26.0 | 22.5 | ||||||||||||||||

| 0.39 | 0.771–0.789 | 0.514–0.526 | 0.386–0.394 | 0.257–0.263 | 31.5 | 26.0 | 22.5 | ||||||||||||||||

| 0.38 | 0.750–0.770 | 0.500–0.513 | 0.375–0.385 | 0.250–0.256 | 31.5 | 26.0 | 22.5 | ||||||||||||||||

| 0.37 | 0.731–0.749 | 0.487–0.499 | 0.366–0.374 | 0.244–0.249 | 31.5 | 25.5 | 22.5 | ||||||||||||||||

| 0.36 | 0.710–0.730 | 0.474–0.486 | 0.355–0.365 | 0.237–0.243 | 31.0 | 25.5 | 22.0 | ||||||||||||||||

| 0.35 | 0.691–0.709 | 0.461–0.473 | 0.346–0.354 | 0.231–0.236 | 31.0 | 25.5 | 22.0 | ||||||||||||||||

| 0.34 | 0.670–0.690 | 0.447–0.460 | 0.335–0.345 | 0.224–0.230 | 31.0 | 25.0 | 22.0 | ||||||||||||||||

| 0.33 | 0.651–0.669 | 0.434–0.446 | 0.326–0.334 | 0.217–0.223 | 30.5 | 25.0 | 22.0 | ||||||||||||||||

| 0.32 | 0.630–0.650 | 0.420–0.433 | 0.315–0.325 | 0.210–0.216 | 30.5 | 25.0 | 21.5 | ||||||||||||||||

| 0.31 | 0.611–0.629 | 0.407–0.419 | 0.306–0.314 | 0.204–0.209 | 30.5 | 25.0 | 21.5 | ||||||||||||||||

| 0.30 | 0.590–0.610 | 0.394–0.406 | 0.295–0.305 | 0.197–0.203 | 30.0 | 24.5 | 21.5 | ||||||||||||||||

| 0.29 | 0.571–0.589 | 0.381–0.393 | 0.286–0.294 | 0.191–0.196 | 30.0 | 24.5 | 21.5 | ||||||||||||||||

| 0.28 | 0.550–0.570 | 0.367–0.380 | 0.275–0.285 | 0.184–0.190 | 29.5 | 24.5 | 21.0 | ||||||||||||||||

| 0.27 | 0.531–0.549 | 0.354–0.366 | 0.266–0.274 | 0.177–0.183 | 29.5 | 24.0 | 21.0 | ||||||||||||||||

| 0.26 | 0.510–0.530 | 0.340–0.353 | 0.255–0.265 | 0.170–0.176 | 29.0 | 24.0 | 21.0 | ||||||||||||||||

| 0.25 | 0.491–0.509 | 0.327–0.339 | 0.246–0.254 | 0.164–0.169 | 29.0 | 23.5 | 20.5 | ||||||||||||||||

| 0.24 | 0.470–0.490 | 0.314–0.326 | 0.235–0.245 | 0.157–0.163 | 29.0 | 23.5 | 20.5 | ||||||||||||||||

| 0.23 | 0.451–0.469 | 0.301–0.313 | 0.226–0.234 | 0.151–0.156 | 28.5 | 23.5 | 20.5 | ||||||||||||||||

| 0.22 | 0.430–0.450 | 0.287–0.300 | 0.215–0.225 | 0.144–0.150 | 28.5 | 23.0 | 20.0 | ||||||||||||||||

| 0.21 | 0.411–0.429 | 0.274–0.286 | 0.206–0.214 | 0.137–0.143 | 28.0 | 23.0 | 20.0 | ||||||||||||||||

| 0.20 | 0.390–0.410 | 0.260–0.273 | 0.195–0.205 | 0.130–0.136 | 27.5 | 22.5 | 19.5 | ||||||||||||||||

| 0.19 | 0.371–0.389 | 0.247–0.259 | 0.186–0.194 | 0.124–0.129 | 27.5 | 22.5 | 19.5 | ||||||||||||||||

| 0.18 | 0.350–0.370 | 0.234–0.246 | 0.175–0.185 | 0.117–0.123 | 27.0 | 22.0 | 19.5 | ||||||||||||||||

| 0.17 | 0.331–0.349 | 0.221–0.233 | 0.166–0.174 | 0.111–0.116 | 27.0 | 22.0 | 19.0 | ||||||||||||||||

| 0.16 | 0.310–0.330 | 0.207–0.220 | 0.155–0.165 | 0.104–0.110 | 26.5 | 21.5 | 19.0 | ||||||||||||||||

| 0.15 | 0.291–0.309 | 0.194–0.206 | 0.146–0.154 | 0.097–0.103 | 26.0 | 21.5 | 18.5 | ||||||||||||||||

| 0.14 | 0.270–0.290 | 0.180–0.193 | 0.135–0.145 | 0.091–0.096 | 26.0 | 21.0 | 18.5 | ||||||||||||||||

| 0.13 | 0.251–0.269 | 0.167–0.179 | 0.126–0.134 | 0.084–0.090 | 25.5 | 21.0 | 18.0 | ||||||||||||||||

| 0.12 | 0.230–0.250 | 0.154–0.166 | 0.115–0.125 | 0.077–0.083 | 25.0 | 20.5 | 18.0 | ||||||||||||||||

| 0.11 | 0.211–0.229 | 0.141–0.153 | 0.106–0.114 | 0.071–0.076 | 24.5 | 20.0 | 17.5 | ||||||||||||||||

| 0.10 | 0.190–0.210 | 0.127–0.140 | 0.095–0.105 | 0.064–0.070 | 24.0 | 19.5 | 17.0 | ||||||||||||||||

| 0.09 | 0.171–0.189 | 0.114–0.126 | 0.086–0.094 | 0.057–0.063 | 23.5 | 19.5 | 17.0 | ||||||||||||||||

| 0.08 | 0.150–0.170 | 0.100–0.113 | 0.075–0.085 | 0.050–0.056 | 23.0 | 19.0 | 16.5 | ||||||||||||||||

| 0.07 | 0.131–0.149 | 0.087–0.099 | 0.066–0.074 | 0.044–0.049 | 22.5 | 18.5 | 16.0 | ||||||||||||||||

| 0.06 | 0.110–0.130 | 0.074–0.086 | 0.055–0.065 | 0.037–0.043 | 22.0 | 18.0 | 15.5 | ||||||||||||||||

| 0.05 | 0.091–0.109 | 0.061–0.073 | 0.046–0.054 | 0.031–0.036 | 21.0 | 17.0 | 15.0 | ||||||||||||||||

| 0.04 | 0.070–0.090 | 0.047–0.060 | 0.035–0.045 | 0.024–0.030 | 20.0 | 16.5 | 14.5 | ||||||||||||||||

| 0.03 | 0.051–0.069 | 0.034–0.046 | 0.026–0.034 | 0.017–0.023 | 19.0 | 15.5 | 13.5 | ||||||||||||||||

| 0.02 | 0.030–0.050 | 0.020–0.033 | 0.015–0.025 | 0.010–0.016 | 17.5 | 14.5 | 12.5 | ||||||||||||||||

| ≤0.01 | ≤0.029 | ≤0.019 | ≤0.014 | ≤0.009 | 15.0 | 12.5 | 11.0 | ||||||||||||||||

| A1in2 =645.16mm2 | |||||||||||||||||||||||

| B1in =25.4mm | |||||||||||||||||||||||

| Variations in Outside Diameter | |||||||||||||||||||||||

| NPS Designator | Permissible Variations in Outside Diameter | ||||||||||||||||||||||

| Over | Under | ||||||||||||||||||||||

| in | mm | in | mm | ||||||||||||||||||||

| 1⁄8 to 11⁄2, incl | 1⁄64 (0.015) | 0.40 | 1⁄64 (0.015) | 0.40 | |||||||||||||||||||

| Over 11⁄2 to 4, incl | 1⁄32 (0.031) | 0.79 | 1⁄32 (0.031) | 0.79 | |||||||||||||||||||

| Over 4 to 8, incl | 1⁄16 (0.062) | 1.59 | 1⁄32 (0.031) | 0.79 | |||||||||||||||||||

| Over 8 to 18, incl | 3⁄32 (0.093) | 2.38 | 1⁄32 (0.031) | 0.79 | |||||||||||||||||||

| Over 18 to 26, incl | 1⁄8 (0.125) | 3.18 | 1⁄32 (0.031) | 0.79 | |||||||||||||||||||

| Over 26 to 34, incl | 5⁄32 (0.156) | 3.97 | 1⁄32 (0.031) | 0.79 | |||||||||||||||||||

| Over 34 to 48, incl | 3⁄16 (0.187) | 4.76 | 1⁄32 (0.031) | 0.79 | |||||||||||||||||||

| Marking | |||||||||||||||||||||||

| Hydro | NDE | Marking | |||||||||||||||||||||

| Yes | No | Test Pressure | |||||||||||||||||||||

| No | Yes | NDE | |||||||||||||||||||||

| No | No | NH | |||||||||||||||||||||

| Yes | Yes | Test Pressure/NDE | |||||||||||||||||||||

|

|||||||||||||||||||||||

|

NPS Designator |

Outside Diameter, in. | Wall Thickness, in. | Schedule Number | Distance, in inches, Between Plates "H" by Equation: |

NPS Designator |

Outside Diameter, in. | Wall Thickness in | Schedule Number |

Distance, in inches, Between Plates "H" by Equation:

|

||||||||||||||

| Grade A | Grades B&C | Grade A | Grades B&C | ||||||||||||||||||||

| 21⁄2 | 2.875 | 0.203 | 40 | 1.456 | 1.545 | 14 | 14.000 | 0.250 | 10 | 2.759 | 3.045 | ||||||||||||

| 0.276 | 80 | 1.694 | 1.779 | 0.312 | 20 | 3.294 | 3.617 | ||||||||||||||||

| 0.375 | 160 | 1.925 | 2.002 | 0.375 | 30 | 3.792 | 4.146 | ||||||||||||||||

| 0.438 | 40 | 4.669 | 5.125 | ||||||||||||||||||||

| 3 | 3.500 | 0.216 | 40 | 1.646 | 1.755 | 0.593 | 60 | 5.234 | 5.647 | ||||||||||||||

| 0.300 | 80 | 1.955 | 2.062 | 0.750 | 80 | 6.064 | 6.494 | ||||||||||||||||

| 0.438 | 160 | 2.306 | 2.398 | 0.937 | 100 | 6.887 | 7.322 | ||||||||||||||||

| 1.093 | 120 | 7.479 | 7.902 | ||||||||||||||||||||

| 31⁄2 | 4.000 | 0.226 | 40 | 1.788 | 1.912 | 1.250 | 140 | 7.974 | 8.397 | ||||||||||||||

| 0.318 | 80 | 2.153 | 2.276 | 1.406 | 160 | 8.416 | 8.827 | ||||||||||||||||

| 4 | 4.500 | 0.237 | 40 | 1.929 | 2.067 | 16 | 16.000 | 0.250 | 10 | 2.284 | 3.124 | ||||||||||||

| 0.337 | 80 | 2.350 | 2.489 | 0.312 | 20 | 3.387 | 3.730 | ||||||||||||||||

| 0.438 | 120 | 2.687 | 2.818 | 0.375 | 30 | 3.915 | 4.294 | ||||||||||||||||

| 0.531 | 160 | 2.896 | 3.022 | 0.500 | 40 | 4.854 | 5.284 | ||||||||||||||||

| 0.656 | 60 | 5.855 | 6.324 | ||||||||||||||||||||

| 5 | 5.563 | 0.258 | 40 | 2.205 | 2.372 | 0.843 | 80 | 6.861 | 7.352 | ||||||||||||||

| 0.375 | 80 | 2.747 | 2.920 | 1.031 | 100 | 7.709 | 8.206 | ||||||||||||||||

| 0.500 | 120 | 3.179 | 3.346 | 1.218 | 120 | 8.426 | 8.919 | ||||||||||||||||

| 0.625 | 160 | 3.509 | 3.667 | 1.438 | 140 | 9.141 | 9.625 | ||||||||||||||||

| 1.593 | 160 | 9.579 | 10.050 | ||||||||||||||||||||

| 6 | 6.625 | 0.280 | 40 | 2.473 | 2.669 | ||||||||||||||||||

| 0.432 | 80 | 3.213 | 3.419 | 18 | 18.000 | 0.250 | 10 | 2.876 | 3.189 | ||||||||||||||

| 0.562 | 120 | 3.682 | 3.884 | 0.312 | 20 | 3.462 | 3.823 | ||||||||||||||||

| 0.719 | 160 | 4.116 | 4.307 | 0.438 | 30 | 4.535 | 4.963 | ||||||||||||||||

| 0.562 | 40 | 5.457 | 5.941 | ||||||||||||||||||||

| 8 | 8.625 | 0.250 | 20 | 2.477 | 2.702 | 0.750 | 60 | 6.656 | 7.185 | ||||||||||||||

| 0.277 | 30 | 2.668 | 2.902 | 0.937 | 80 | 7.663 | 8.214 | ||||||||||||||||

| 0.322 | 40 | 2.964 | 3.210 | 1.156 | 100 | 8.657 | 9.216 | ||||||||||||||||

| 0.406 | 60 | 3.451 | 3.711 | 1.375 | 120 | 9.495 | 10.043 | ||||||||||||||||

| 0.500 | 80 | 3.914 | 4.181 | 1.562 | 140 | 10.115 | 10.660 | ||||||||||||||||

| 0.593 | 100 | 4.305 | 4.573 | 1.781 | 160 | 10.665 | 11.198 | ||||||||||||||||

| 0.719 | 120 | 4.750 | 5.013 | ||||||||||||||||||||

| 0.812 | 140 | 5.036 | 5.293 | 20 | 20.000 | 0.250 | 10 | 2.919 | 3.242 | ||||||||||||||

| 0.906 | 160 | 5.288 | 5.538 | 0.375 | 20 | 4.101 | 4.521 | ||||||||||||||||

| 0.500 | 30 | 5.143 | 5.632 | ||||||||||||||||||||

| 10 | 10.750 | 0.250 | 20 | 2.615 | 2.868 | 0.593 | 40 | 5.841 | 6.367 | ||||||||||||||

| 0.307 | 30 | 3.054 | 3.333 | 0.812 | 60 | 7.272 | 7.856 | ||||||||||||||||

| 0.365 | 40 | 3.459 | 3.757 | 1.031 | 80 | 8.464 | 9.072 | ||||||||||||||||

| 0.500 | 60 | 4.268 | 4.592 | 1.281 | 100 | 9.601 | 10.221 | ||||||||||||||||

| 0.593 | 80 | 4.738 | 5.070 | 1.500 | 120 | 10.452 | 11.069 | ||||||||||||||||

| 0.719 | 100 | 5.320 | 5.621 | 1.750 | 140 | 11.284 | 11.889 | ||||||||||||||||

| 0.843 | 120 | 5.747 | 6.077 | 1.968 | 160 | 11.913 | 12.504 | ||||||||||||||||

| 1.000 | 140 | 6.242 | 6.564 | ||||||||||||||||||||

| 1.125 | 160 | 6.580 | 6.892 | 24 | 24.000 | 0.250 | 10 | 2.986 | 3.326 | ||||||||||||||

| 0.375 | 20 | 4.236 | 4.686 | ||||||||||||||||||||

| 12 | 12.750 | 0.250 | 20 | 2.711 | 2.985 | 0.562 | 30 | 5.869 | 6.437 | ||||||||||||||

| 0.330 | 30 | 3.366 | 3.683 | 0.687 | 40 | 6.831 | 7.454 | ||||||||||||||||

| 0.406 | 40 | 3.921 | 4.266 | 0.968 | 60 | 8.690 | 9.390 | ||||||||||||||||

| 0.562 | 60 | 4.892 | 5.271 | 1.218 | 80 | 10.061 | 10.793 | ||||||||||||||||

| 0.687 | 80 | 5.542 | 5.934 | 1.531 | 100 | 11.449 | 12.244 | ||||||||||||||||

| 0.843 | 100 | 6.231 | 6.627 | 1.812 | 120 | 12.585 | 13.32 | ||||||||||||||||

| 1.000 | 120 | 6.817 | 7.209 | 2.062 | 140 | 13.424 | 14.150 | ||||||||||||||||

| 1.125 | 140 | 7.222 | 7.607 | 2.343 | 160 | 14.248 | 14.958 | ||||||||||||||||

| 1.312 | 160 | 7.747 | 8.119 | ||||||||||||||||||||

| Calculated “H” Values for Seamless Pipe Continued Units | |||||||||||||||||||||||

|

NPS Designator |

Outside Diameter, in. | Wall Thickness, in. | Schedule Number | Distance, in inches, Between Plates "H" by Equation: |

NPS Designator |

Outside Diameter, in. | Wall Thickness in | Schedule Number | Distance, in inches, Between Plates "H" by Equation: | ||||||||||||||

| Grade A | Grades B&C | Grade A | Grades B&C | ||||||||||||||||||||

| 2 1⁄2 | 73.0 | 5.16 | 40 | 37.0 | 39.2 | 14 | 355.6 | 6.35 | 10 | 70.1 | 77.3 | ||||||||||||

| 7.01 | 80 | 43.0 | 45.2 | 7.92 | 20 | 83.7 | 91.8 | ||||||||||||||||

| 9.52 | 160 | 48.9 | 50.8 | 9.52 | 30 | 96.3 | 105.3 | ||||||||||||||||

| 11.13 | 40 | 118.6 | 130.2 | ||||||||||||||||||||

| 3 | 88.9 | 5.49 | 40 | 41.8 | 44.6 | 15.06 | 60 | 132.9 | 143.4 | ||||||||||||||

| 7.62 | 80 | 49.6 | 52.4 | 19.05 | 80 | 154.0 | 165.0 | ||||||||||||||||

| 11.13 | 160 | 58.6 | 60.9 | 23.80 | 100 | 174.9 | 186.0 | ||||||||||||||||

| 27.76 | 120 | 190.0 | 200.7 | ||||||||||||||||||||

| 31⁄2 | 101.6 | 5.74 | 40 | 45.4 | 48.6 | 31.75 | 140 | 202.5 | 213.3 | ||||||||||||||

| 8.08 | 80 | 54.7 | 57.8 | 35.71 | 160 | 213.8 | 224.2 | ||||||||||||||||

| 4 | 114.3 | 6.02 | 40 | 49.0 | 52.5 | 16 | 406.4 | 6.35 | 10 | 71.7 | 79.4 | ||||||||||||

| 8.56 | 80 | 59.7 | 63.2 | 7.92 | 20 | 89.0 | 94.7 | ||||||||||||||||

| 11.13 | 120 | 67.0 | 71.6 | 9.52 | 30 | 99.4 | 109.1 | ||||||||||||||||

| 13.49 | 160 | 73.6 | 76.8 | 12.70 | 40 | 123.3 | 143.2 | ||||||||||||||||

| 16.66 | 60 | 148.7 | 160.6 | ||||||||||||||||||||

| 5 | 141.3 | 6.55 | 40 | 56.0 | 60.2 | 21.41 | 80 | 174.3 | 186.7 | ||||||||||||||

| 9.52 | 80 | 69.8 | 74.2 | 26.19 | 100 | 195.8 | 208.4 | ||||||||||||||||

| 12.70 | 120 | 80.8 | 85.0 | 30.94 | 120 | 214.0 | 226.6 | ||||||||||||||||

| 15.88 | 160 | 89.1 | 93.1 | 36.53 | 140 | 232.2 | 244.5 | ||||||||||||||||

| 40.46 | 160 | 243.3 | 255.3 | ||||||||||||||||||||

| 6 | 168.3 | 7.11 | 40 | 62.8 | 67.8 | ||||||||||||||||||

| 10.97 | 80 | 81.6 | 86.8 | 18 | 457.2 | 6.35 | 10 | 73.0 | 81.0 | ||||||||||||||

| 14.27 | 120 | 93.5 | 98.6 | 7.92 | 20 | 87.9 | 97.1 | ||||||||||||||||

| 18.24 | 160 | 104.6 | 109.4 | 11.13 | 30 | 115.2 | 126.1 | ||||||||||||||||

| 14.27 | 40 | 139.5 | 150.9 | ||||||||||||||||||||

| 8 | 219.1 | 6.35 | 20 | 63.0 | 68.6 | 19.05 | 60 | 169.1 | 182.5 | ||||||||||||||

| 7.04 | 30 | 67.8 | 73.7 | 23.80 | 80 | 194.6 | 208.6 | ||||||||||||||||

| 8.18 | 40 | 75.3 | 81.5 | 29.36 | 100 | 219.9 | 234.1 | ||||||||||||||||

| 10.31 | 60 | 87.7 | 94.3 | 34.92 | 120 | 241.2 | 255.1 | ||||||||||||||||

| 12.70 | 80 | 99.4 | 106.2 | 39.67 | 140 | 256.9 | 270.7 | ||||||||||||||||

| 15.06 | 100 | 109.4 | 116.2 | 45.24 | 160 | 270.9 | 284.4 | ||||||||||||||||

| 18.24 | 120 | 120.6 | 127.3 | ||||||||||||||||||||

| 20.62 | 140 | 127.9 | 134.4 | 20 | 508.0 | 6.35 | 10 | 74.1 | 82.4 | ||||||||||||||

| 23.01 | 160 | 134.3 | 140.7 | 9.52 | 20 | 104.2 | 114.8 | ||||||||||||||||

| 12.70 | 30 | 130.6 | 143.0 | ||||||||||||||||||||

| 10 | 273.0 | 6.35 | 20 | 66.4 | 72.8 | 15.06 | 40 | 148.4 | 161.7 | ||||||||||||||

| 7.80 | 30 | 77.6 | 84.7 | 20.62 | 60 | 184.7 | 199.5 | ||||||||||||||||

| 9.27 | 40 | 87.9 | 95.4 | 26.19 | 80 | 215.0 | 230.4 | ||||||||||||||||

| 12.70 | 60 | 108.4 | 116.6 | 32.54 | 100 | 243.9 | 259.6 | ||||||||||||||||

| 15.06 | 80 | 120.4 | 128.8 | 38.10 | 120 | 265.5 | 281.2 | ||||||||||||||||

| 18.24 | 100 | 135.1 | 142.8 | 44.45 | 140 | 286.6 | 302.0 | ||||||||||||||||

| 21.41 | 120 | 146.0 | 154.4 | 49.99 | 160 | 302.6 | 317.6 | ||||||||||||||||

| 25.40 | 140 | 158.6 | 166.7 | ||||||||||||||||||||

| 28.58 | 160 | 167.1 | 175.1 | 24 | 609.6 | 6.35 | 10 | 75.8 | 84.5 | ||||||||||||||

| 9.52 | 20 | 107.6 | 119.0 | ||||||||||||||||||||

| 12 | 323.8 | 6.35 | 20 | 68.9 | 75.8 | 14.27 | 30 | 149.1 | 163.5 | ||||||||||||||

| 8.38 | 30 | 85.5 | 93.6 | 17.35 | 40 | 173.5 | 189.3 | ||||||||||||||||

| 10.31 | 40 | 99.6 | 108.4 | 24.59 | 60 | 220.7 | 238.5 | ||||||||||||||||

| 14.27 | 60 | 124.3 | 133.9 | 30.94 | 80 | 255.6 | 274.1 | ||||||||||||||||

| 17.35 | 80 | 140.8 | 150.7 | 38.89 | 100 | 290.8 | 311.0 | ||||||||||||||||

| 21.41 | 100 | 158.3 | 168.3 | 46.02 | 120 | 319.7 | 338.6 | ||||||||||||||||

| 25.40 | 120 | 173.2 | 183.1 | 52.37 | 140 | 341.0 | 359.4 | ||||||||||||||||

| 28.58 | 140 | 183.4 | 193.2 | 59.51 | 160 | 361.9 | 379.9 | ||||||||||||||||

| 33.32 | 160 | 196.8 | 206.2 | ||||||||||||||||||||

| X2. MINIMUM WALL THICKNESS | |||||||||||||||||||||||

| X2.1 Table X2.1 lists minimum wall thicknesses for nomi-al pipe wall thickness. | |||||||||||||||||||||||

| TABLE X2.1 Mimimum Wall Thicknesses on Inspection for Nominal (Average) Pipe Wall Thicknesses | |||||||||||||||||||||||

| NOTE 1—The following equation, upon which this table is based, may be applied to calculate minimum wall thickness from nominal (average) wall thickness: | |||||||||||||||||||||||

| tn X 0.875 5 = tm | |||||||||||||||||||||||

| where: | |||||||||||||||||||||||

| tn = nominal (average) wall thickness, in. and | |||||||||||||||||||||||

| tm = minimum wall thickness, in. | |||||||||||||||||||||||

|

The wall thickness is expressed to three decimal places, the fourth decimal place being carried forward or dropped, in accordance with Practice E 29. NOTE 2—This table covers some wall thicknesses associated with standard pipe sizes but is not meant to imply that these are the only thicknesses obtainable under this specification. |

|||||||||||||||||||||||

|

Nominal (Average) Thickness (tn) |

Minimum Thickness on Inspection (tm) |

Nominal (Average) Thickness (tn) |

Minimum Thickness on Inspection (tm) |

Nominal (Average) Thickness (tn) |

Minimum Thickness on Inspection (tm) | ||||||||||||||||||

| in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | ||||||||||||

| 0.068 | 1.73 | 0.060 | 1.52 | 0.281 | 7.14 | 0.246 | 6.25 | 0.864 | 21.94 | 0.756 | 19.20 | ||||||||||||

| 0.083 | 2.11 | 0.073 | 1.85 | 0.294 | 7.47 | 0.257 | 6.53 | 0.875 | 22.22 | 0.766 | 19.46 | ||||||||||||

| 0.088 | 2.24 | 0.077 | 1.96 | 0.300 | 7.62 | 0.262 | 6.65 | 0.906 | 23.01 | 0.793 | 20.14 | ||||||||||||

| 0.091 | 2.31 | 0.080 | 2.03 | 0.307 | 7.80 | 0.269 | 6.83 | 0.938 | 23.82 | 0.821 | 20.85 | ||||||||||||

| 0.095 | 2.41 | 0.083 | 2.11 | 0.308 | 7.82 | 0.270 | 6.86 | 0.968 | 24.59 | 0.847 | 21.51 | ||||||||||||

| 0.109 | 2.77 | 0.095 | 2.41 | 0.312 | 7.92 | 0.273 | 6.93 | 1.000 | 25.40 | 0.875 | 22.22 | ||||||||||||

| 0.113 | 2.87 | 0.099 | 2.51 | 0.318 | 8.07 | 0.278 | 7.06 | 1.031 | 26.19 | 0.902 | 22.91 | ||||||||||||

| 0.119 | 3.02 | 0.104 | 2.64 | 0.322 | 8.18 | 0.282 | 7.16 | 1.062 | 26.97 | 0.929 | 23.60 | ||||||||||||

| 0.125 | 3.18 | 0.109 | 2.77 | 0.330 | 8.38 | 0.289 | 7.34 | 1.094 | 27.79 | 0.957 | 24.31 | ||||||||||||

| 0.126 | 3.20 | 0.110 | 2.79 | 0.337 | 8.56 | 0.295 | 7.49 | 1.125 | 28.58 | 0.984 | 24.99 | ||||||||||||

| 0.133 | 3.38 | 0.116 | 2.95 | 0.344 | 8.74 | 0.301 | 7.64 | 1.156 | 29.36 | 1.012 | 25.70 | ||||||||||||

| 0.140 | 3.56 | 0.122 | 3.10 | 0.358 | 9.09 | 0.313 | 7.95 | 1.219 | 30.96 | 1.066 | 27.08 | ||||||||||||

| 0.141 | 3.58 | 0.123 | 3.12 | 0.365 | 9.27 | 0.319 | 8.10 | 1.250 | 31.75 | 1.094 | 27.79 | ||||||||||||

| 0.145 | 3.68 | 0.127 | 3.23 | 0.375 | 9.52 | 0.328 | 8.33 | 1.281 | 32.54 | 1.121 | 28.47 | ||||||||||||

| 0.147 | 3.73 | 0.129 | 3.28 | 0.382 | 9.70 | 0.334 | 8.48 | 1.312 | 33.32 | 1.148 | 29.16 | ||||||||||||

| 0.154 | 3.91 | 0.135 | 3.43 | 0.400 | 10.16 | 0.350 | 8.89 | 1.375 | 34.92 | 1.203 | 30.56 | ||||||||||||

| 0.156 | 3.96 | 0.136 | 3.45 | 0.406 | 10.31 | 0.355 | 9.02 | 1.406 | 35.71 | 1.230 | 31.24 | ||||||||||||

| 0.172 | 4.37 | 0.150 | 3.81 | 0.432 | 10.97 | 0.378 | 9.60 | 1.438 | 36.53 | 1.258 | 31.95 | ||||||||||||

| 0.179 | 4.55 | 0.157 | 3.99 | 0.436 | 11.07 | 0.382 | 9.70 | 1.500 | 38.10 | 1.312 | 33.32 | ||||||||||||

| 0.188 | 4.78 | 0.164 | 4.17 | 0.438 | 11.12 | 0.383 | 9.73 | 1.531 | 38.89 | 1.340 | 34.04 | ||||||||||||

| 0.191 | 4.85 | 0.167 | 4.24 | 0.469 | 11.91 | 0.410 | 10.41 | 1.562 | 39.67 | 1.367 | 34.72 | ||||||||||||

| 0.200 | 5.08 | 0.175 | 4.44 | 0.500 | 12.70 | 0.438 | 11.13 | 1.594 | 40.49 | 1.395 | 35.43 | ||||||||||||

| 0.203 | 5.16 | 0.178 | 4.52 | 0.531 | 13.49 | 0.465 | 11.81 | 1.635 | 41.53 | 1.431 | 36.35 | ||||||||||||

| 0.210 | 5.33 | 0.184 | 4.67 | 0.552 | 14.02 | 0.483 | 12.27 | 1.750 | 44.45 | 1.531 | 38.89 | ||||||||||||

| 0.216 | 5.49 | 0.189 | 4.80 | 0.562 | 14.27 | 0.492 | 12.50 | 1.781 | 45.24 | 1.558 | 39.57 | ||||||||||||

| 0.218 | 5.54 | 0.191 | 4.85 | 0.594 | 15.09 | 0.520 | 13.21 | 1.812 | 46.02 | 1.586 | 40.28 | ||||||||||||

| 0.219 | 5.56 | 0.192 | 4.88 | 0.600 | 15.24 | 0.525 | 13.34 | 1.875 | 47.62 | 1.641 | 41.68 | ||||||||||||

| 0.226 | 5.74 | 0.198 | 5.03 | 0.625 | 15.88 | 0.547 | 13.89 | 1.969 | 50.01 | 1.723 | 43.76 | ||||||||||||

| 0.237 | 6.02 | 0.207 | 5.26 | 0.656 | 16.66 | 0.574 | 14.58 | 2.000 | 50.80 | 1.750 | 44.45 | ||||||||||||

| 0.250 | 6.35 | 0.219 | 5.56 | 0.674 | 17.12 | 0.590 | 14.99 | 2.062 | 52.37 | 1.804 | 45.82 | ||||||||||||

| 0.258 | 6.55 | 0.226 | 5.74 | 0.688 | 17.48 | 0.602 | 15.29 | 2.125 | 53.98 | 1.859 | 47.22 | ||||||||||||

| 0.276 | 7.01 | 0.242 | 6.15 | 0.719 | 18.26 | 0.629 | 15.98 | 2.200 | 55.88 | 1.925 | 48.90 | ||||||||||||

| 0.277 | 7.04 | 0.242 | 6.15 | 0.750 | 19.05 | 0.656 | 16.66 | 2.344 | 59.54 | 2.051 | 52.10 | ||||||||||||

| 0.279 | 7.09 | 0.244 | 6.19 | 0.812 | 20.62 | 0.710 | 18.03 | 2.500 | 63.50 | 2.188 | 55.58 | ||||||||||||

| 0.280 | 7.11 | 0.245 | 6.22 | 0.844 | 21.44 | 0.739 | 18.77 | ||||||||||||||||

| Wall Thickness: Welded and Seamless Wrought Steel Pipe, ANSI /ASME B36.10M | |||||||||||||||||||||||

| Schedule (SCH) | SCH 5 | SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | |||||||||||||

| SCH 120 | SCH 160 | SCH XXS | SCH XX.H | ||||||||||||||||||||

| End of pipe end | |||||||||||||||||||||||

| Plain Ends (PE) | The PE pipes will generally be used for the smaller diameters pipe systems and in combination with Slip On flanges and Socket Weld fittings and flanges. | ||||||||||||||||||||||

| Threaded Ends (TE) | The TE implementation speaks for itself, this performance will generally used for small diameters pipe systems, and the connections will be made with threaded flanges and threaded fittings. | ||||||||||||||||||||||

| Beveled Ends (BE) | The BE implementation is applied to all diameters of buttweld flanges or buttweld fittings, and will be directly welded (with a small gap 3-4 mm) to each other or to the pipe. Ends are mostly be beveled to angle 30° (+ 5° / -0°) with a root face of 1.6 mm (± 0.8 mm). | ||||||||||||||||||||||

| Grooved ends | (example Victaulic pipes): these are pipes that allow a quick connection, used for non-critical applications | ||||||||||||||||||||||

| Threaded and coupled ends |

(T&C), generally used for gas distribution, Threaded connections are the most common pipe fittings used in oil and gas transportation systems. Due to external vibrations, cyclic loads, and pollution, the fitting parts may start getting loose, which could result in pipeline leaks and other environmental disasters. It is of great significance to develop a reliable technique that could provide… |

||||||||||||||||||||||

| Type end : Plain Ends / Beveled Ends: Tubes – Pipe | |||||||||||||||||||||||

|

• Bevel End (BE) • Bevel Both Ends (BBE) • Bevel Large End (BLE) • Bevel One End (BOE) • Bevel Small End (BSE) • Bevel for Welding (BFW) • Buttweld End (BE) |

• End of Pipe (EOP) • Flange One End (FOE) • Plain End (PE) • Plain Both Ends (PBE) • Plain One End (POE) • Thread End (TE) • Thread Both Ends (TBE) |

• Thread Large End (TLE) • Thread One End (TOE) • Thread Small End (TSE) • Threads Only (TO) • Threads per Inch (TP I) |

|||||||||||||||||||||

| Plastic End Caps for Tubing and Pipe Ends | |||||||||||||||||||||||

| Pipe End Caps | Pipe End Plugs | Threaded Pipe Caps | Threaded Pipe Plugs | ||||||||||||||||||||

| Standard: Pipe of Tube | |||||||||||||||||||||||

| The American Society Of Mechanical Engineers | American National Standards Institute | ||||||||||||||||||||||

| ASME B36.19M | ANSI B36.19M | ||||||||||||||||||||||

| ASME B36.10M | ANSI B36.10M | ||||||||||||||||||||||

| Product related keywords | |

| Seamless Carbon Steel Pipe for High-Temperature Pipe A106 Grade C | |

| Seamless pipe, A106 Grade C | Pipe A106 Grade C, SMLS |

| Seamless pipe, A106 Gr.C | Pipe A106 Gr.C, SMLS |

| Seamless Pipe A106 Grade C, Galvanized | Pipe A106 Grade C, SMLS, Galvanized |

| Seamless Pipe A106 Grade C, Zinc coated | Pipe A106 Grade C, SMLS, Zinc coated |

| Seamless Pipe A106 Grade C, Pickled and oiled | Pipe A106 Grade C, SMLS, Pickled and oiled |

| Seamless Pipe A106 Grade C, SCH 5 | Seamless Pipe A106 Grade C, SCH 10 |

| Seamless Pipe A106 Grade C, SCH 20 | Seamless Pipe A106 Grade C, SCH 30 |

| Seamless Pipe A106 Grade C, SCH STD | Seamless Pipe A106 Grade C, SCH 40 |

| Seamless Pipe A106 Grade C, SCH 60 | Seamless Pipe A106 Grade C, SCH XS |

| Seamless Pipe A106 Grade C, SCH 80 | Seamless Pipe A106 Grade C, SCH 100 |

| Seamless Pipe A106 Grade C, SCH 120 | Seamless Pipe A106 Grade C, SCH 160 |

| Seamless Pipe A106 Grade C, SCH XXS | Seamless Pipe A106 Grade C, SCH XX.H |

| Coating Pipe A106 Grade C | |||||

|

External FBE Coating Pipe (Pipe PP) – Pipe PE Pipe Epoxy (FBE) |

Fusion Bonded Epoxy (FBE) coating protects pipe surfaces against corrosion. Double or triple layers of FBE may even increase the resistance to friction and abrasion. FBE coating is also used as the primer layer in 3-layer PE/PP coating systems. Electrostatic epoxy powder is sprayed onto a pipe at a temperature typically around 220 – 235°C. On reaching the hot pipe surface, the epoxy powder melts and forms an uniform layer of epoxy coating on the pipe. |

||||

|

3 Layer PP/PE Coating Pipe (Pipe FBE ) – ( Pipe PE/PP layer |

In addition to an anti-corrosion layer of FBE coating, mechanical protection can be added by applying a layer of Polyethylene (PE) or Polypropylene (PP). An adhesive layer takes care of the bonding between the FBE and PE/PP layer. Granules of PE/PP are extruded onto the passing pipe, forming a solid coating layer. Side extrusion is most commonly used, where a sheet of PE/PP is wrapped around a pipe. For smaller diameter pipes, so-called sleeve/ring extrusion is a common process. |

||||

|

External Liquid Coating Pipe (Pipe PU) |

With external liquid coating, coating is applied to the outside pipe surface by a spraying system, providing corrosion protection for the pipe surfaces. There are multiple coating types available e.g. liquid epoxy, polyurethane (PU), or e.g. (UV-curable) laquer. |

||||

|

Internal Liquid Lining Pipe polyurethane (PU), or 2-component coating. |

Internal liquid lining is a coating layer on an internal pipe surface to protect against corrosion or to optimize flow efficiency. There are multiple coating types available such as liquid epoxy, polyurethane (PU), or 2-component coating. After placing the pipe in the internal liquid coating station, the pipe ends are sealed off and a lance with the spraying gun system is moved through the pipe. Pre-heating could be an option for internal liquid coating. |

||||

|

Internal FBE Lining Pipe Fusion Bonded Epoxy (FBE) |

An internal FBE coating is used to protect the inner surfaces of steel pipes from the influence of corrosion and light mechanical impacts and it provides excellent resistance to cathodic disbondment. The internal Fusion Bonded Epoxy (FBE) system is based on an epoxy powder spray system, mounted on a lance. The lance moves through the pipe while the epoxy powder is sprayed onto the internal pipe surface. The pipe must be heated so that the epoxy powder melts onto the pipe. After FBE application, the layer requires curing. |

||||

|

Cement Mortar Lining (CML) Pipe |

Cement Mortar Lining (CML) is a method for applying a mixture of sand, cement and water onto internal pipe surfaces using a centrifugal spinning or pooring method. A smooth and compact layer of cement mortar protects water pipes against corrosion and abrasion. A characteristic of CML is that blasting the pipe surfaces is not necessarily required prior to the CML application. Selmers has solutions for factory applied and in-situ applied CML. |

||||

|

Concrete Weight Coating 3LPE/PP-coated Pipe |

During the concrete weight coating process, concrete is applied onto the pipe. The concrete layer adds additional weight to pipes to compensate the buoyancy of submarine pipelines, and it also provides protection from external influences. Impingement: 3LPE/PP-coated pipes with weld cage or wire mesh reinforcement. Concrete is sprayed at the pipe by high speed application drums. Compression: FBE or 3LPE/PP coated pipes with concrete wrapped around the pipe along with wire mesh reinforcement. |

||||

|

PU Foam Coating polyurethane foam (PUF) Pipe |

To keep substances in a pipeline at the correct temperature, polyurethane foam (PUF) insulation coating is commonly used for hot oil transmission lines as well as in district heating and cooling. Pipe-in-pipe application consists of an inner pipe and an outer jacket; the space between them is filled with PUF. Another manner for applying PUF is spraying PUF onto a rotating pipe, with an optional extra mechanical protection layer. |

||||

|

PP Foam Coating Multi-layer coating with polypropylene (PP) Pipe |

Multi-layer coating with polypropylene (PP) foam providing high thermal insulation; this is used for deepwater pipeline projects. In some cases glass synthetic PP (PP enforced with glass fibre spheres) is used instead of PP foam. On top of a 3-layer PP coating, various layers of PP foam ensure a pipe gets the insulating characteristics required. Finally, mechanical protection is added with a solid top layer of PP. |

||||

| Material Lined Pipe / Lining Pipe A106 Grade C | |||||

| Teflon (PTFE) Lined Pipe | Teflon (PTFE) Lining Pipe | Cement mortar Lined Pipe | |||

| Cement mortar Lining Pipe | Liquid epoxy Lined Pipe | Liquid epoxy Lining Pipe | |||

| Glass Lined Pipe | Glass Lining Pipe | Fusion bonded epoxy (FBE) Lining Pipe | |||

| Fusion bonded epoxy (FBE) Lined Pipe | Polyethylene Lining Pipe | Bituminous asphalt Lined Pipe | |||

| Polyethylene Lined Pipe | Bituminous asphalt Lining Pipe | bitum Lined Pipe | |||

| bitum Lining Pipe | Zinc Lined Pipe | Zinc Lining Pipe | |||

| galvanized Lined Pipe | galvanized Lining Pipe | PFA-Lined Pipe | |||

| PFA Lining Pipe | Rubber Lined Pipe | NRB Lined Pipe | |||

| Rubber Lining Pipe | NRB Lining Pipe | Polypropylene (PP) Lined Pipe | |||

| Polypropylene (PP) Lining Pipe | Ethylene tetraflurorethylene Lined Pipe | Ethylene tetraflurorethylene Lining Pipe | |||

| ETFE Lined Pipe | ETFE Lining Pipe | polytetrafluroethylene Lined Pipe | |||

| polytetrafluroethylene Lining Pipe | Polyvinylidene Fluoride Lined Pipe | PVDF Lining Pipe | |||

| Polyvinylidene Fluoride Lining Pipe | Perfluoroalkoxy alkane Lined Pipe | PVDF Lined Pipe | |||

| Fluorinated ethylene propylene Lined Pipe | Fluorinated ethylene propylene Lining Pipe | ||||

| EFP Lined Pipe | EFP Lining Pipe | ||||

| Pipe Coating ( Coated Pipes) A106 Grade C | |||||

| Three-layer Polyethylene (3LPE) Pipe | 3 layers Polypropylene (3LPP) Pipe | Epoxy | |||

| Polypropylene (PUR) Pipe | Fusion Bonded Epoxy (FBE) Pipe | pickl. | |||

| 3-Layer Polyolefin Coatings | Asphalt enameled and polyurethane (PUR) Pipe | soaked in oil | |||

| 2-Layer Polyolefin Coatings | Fusion Bonded and Liquid Bonded Epoxy, pipe | galvanized | |||

| Fusion Bonded Epoxy Coating | 1-Layer Polyolefin Coatings | 3 Layer PP/PE Coating | |||

| 3 LPE (External 3 Layer Polyethylene) |

Flow Efficiency Coatings for gas pipelines Liquid Epoxy Coatings for water pipelines |

pickled | |||

| 3 LPP (External 3 Layer Polypropylene) | FBE (External Fusion Bonded Epoxy | External Liquid Coating | |||

| Internal Liquid Lining | External FBE Coating | Internal FBE Lining | |||

| Cement Mortar Lining | Concrete Weight Coating | PU Foam Coating | |||

| Black Coated | PP Foam Coating | phosphated | |||

| zinc coated | hot dipped galvanized | hot-dipped zinc-coated | oiled and plugged | ||

| pickled and oiled | cold galvanized | external protection | |||

| Dimensions of Steel Pipes ASME B36.10 and B36.19 | ||||||

| Seamless Carbon Steel Pipe for High-Temperature Pipe A106 Grade C | ||||||

| 1/2 inches to 2 inches | ||||||

| NPS | 1/2" | 3/4" | 1" | 1¼" | 1½" | 2" |

| OD | 21.3 | 26.7 | 33.4 | 42.2 | 48.3 | 60.3 |

| Wall Thickness | ||||||

| Sch 5 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 |

| Sch 5S | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 |

| Sch 10 | 2.11 | 2.11 | 2.77 | 2.77 | 2.77 | 2.77 |

| Sch 10S | 2.11 | 2.11 | 2.77 | 2.77 | 2.77 | 2.77 |

| Sch 20 | – | … | – | … | – | … |

| Sch 30 | 2.41 | 2.41 | 2.90 | 2.97 | 3.18 | 3.18 |

| STD | 2.77 | 2.87 | 3.38 | 3.56 | 3.68 | 3.91 |

| Sch 40 | 2.77 | 2.87 | 3.38 | 3.56 | 3.68 | 3.91 |

| Sch 40S | 2.77 | 2.87 | 3.38 | 3.56 | 3.68 | 3.91 |

| Sch 60 | – | … | – | … | – | … |

| XS | 3.73 | 3.91 | 4.55 | 4.85 | 5.08 | 5.54 |

| Sch 80 | 3.73 | 3.91 | 4.55 | 4.85 | 5.08 | 5.54 |

| Sch 80S | 3.73 | 3.91 | 4.55 | 4.85 | 5.08 | 5.54 |

| Sch 100 | – | … | – | … | – | … |

| Sch 120 | – | … | – | … | – | … |

| Sch 140 | – | … | – | … | – | … |

| XXS | 7.47 | 7.82 | 9.09 | 9.70 | 10.15 | 11.07 |

| Sch 160 | 4.78 | 5.56 | 6.35 | 6.35 | 7.14 | 8.74 |

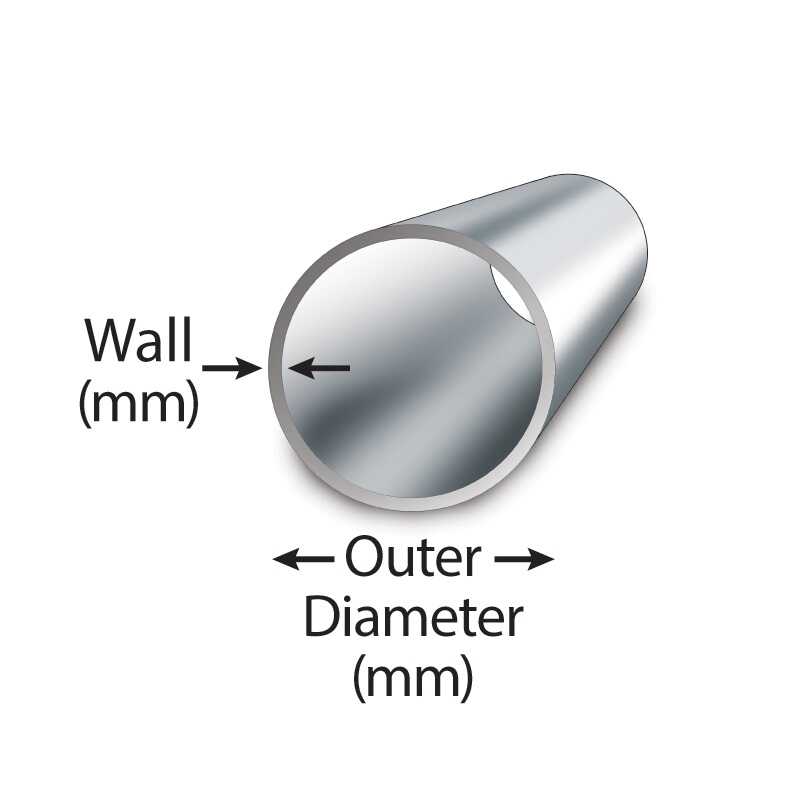

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 2 1/2 inches to 5 inches | ||||||

| NPS | 2½" | 3" | 3½" | 4" | 5" | |

| OD | 73 | 88.9 | 101.6 | 114.3 | 141.3 | |

| Wall Thickness | ||||||

| Sch 5 | 2.11 | 2.11 | 2.11 | 2.11 | 2.77 | |

| Sch 5S | 2.11 | 2.11 | 2.11 | 2.11 | 2.77 | |

| Sch 10 | 3.05 | 3.05 | 3.05 | 3.05 | 3.40 | |

| Sch 10S | 3.05 | 3.05 | 3.05 | 3.05 | 3.40 | |

| Sch 20 | … | … | ||||

| Sch 30 | 4.78 | 4.78 | 4.78 | 4.78 | … | |

| STD | 5.16 | 5.49 | 5.74 | 6.02 | 6.55 | |

| Sch 40 | 5.16 | 5.49 | 5.74 | 6.02 | 6.55 | |

| Sch 40S | 5.16 | 5.49 | 5.74 | 6.02 | 6.55 | |

| Sch 60 | … | … | ||||

| XS | 7.01 | 7.62 | 8.08 | 8.56 | 9.53 | |

| Sch 80 | 7.01 | 7.62 | 8.08 | 8.56 | 9.53 | |

| Sch 80S | 7.01 | 7.62 | 8.08 | 8.56 | 9.53 | |

| Sch 100 | … | … | ||||

| Sch 120 | … | 11.13 | 12.7 | |||

| Sch 140 | … | … | ||||

| XXS | 14.02 | 15.24 | 17.12 | 19.05 | ||

| Sch 160 | 9.53 | 11.13 | 13.49 | 15.88 | ||

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 6 inches to 14 inches | ||||||

| NPS | 6" | 8" | 10" | 12" | 14" | |

| OD | 168.3 | 219 | 273 | 323.9 | 355.6 | |

| Wall Thickness | ||||||

| Sch 5 | 2.77 | 2.77 | 3.40 | 3.96 | 3.96 | |

| Sch 5S | 2.77 | 2.77 | 3.40 | 3.96 | 3.96 | |

| Sch 10 | 3.40 | 3.76 | 4.19 | 4.57 | 6.35 | |

| Sch 10S | 3.40 | 3.76 | 4.19 | 4.57 | 4.78 | |

| Sch 20 | 6.35 | 6.35 | 6.35 | 7.92 | ||

| Sch 30 | 7.04 | 7.80 | 8.38 | 9.53 | ||

| STD | 7.11 | 8.18 | 9.27 | 9.53 | 9.53 | |

| Sch 40 | 7.11 | 8.18 | 9.27 | 10.31 | 11.13 | |

| Sch 40S | 7.11 | 8.18 | 9.27 | 9.53 | 9.53 | |

| Sch 60 | 10.31 | 12.70 | 14.27 | 15.06 | ||

| XS | 10.97 | 12.70 | 12.70 | 12.70 | 12.70 | |

| Sch 80 | 10.97 | 12.70 | 15.09 | 17.48 | 19.05 | |

| Sch 80S | 10.97 | 12.70 | 12.70 | 12.70 | 12.70 | |

| Sch 100 | 15.09 | 18.26 | 21.44 | 23.83 | ||

| Sch 120 | 14.27 | 18.26 | 21.44 | 25.40 | 27.79 | |

| Sch 140 | 20.62 | 25.40 | 28.58 | 31.75 | ||

| XXS | 21.95 | 22.23 | 25.40 | 25.40 | ||

| Sch 160 | 18.26 | 23.01 | 28.58 | 33.32 | 35.71 | |

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 16 inches to 24 inches | ||||||

| NPS | 16" | 18" | 20" | 22" | 24" | |

| OD | 406.04 | 457.2 | 508 | 558.8 | 609.6 | |

| Wall Thickness | ||||||

| Sch 5 | 4.19 | 4.19 | 4.78 | 4.78 | 5.54 | |

| Sch 5S | 4.19 | 4.19 | 4.78 | 4.78 | 5.54 | |

| Sch 10 | 6.35 | 6.35 | 6.35 | 6.35 | 6.35 | |

| Sch 10S | 4.78 | 4.78 | 5.54 | 5.54 | 6.35 | |

| Sch 20 | 7.92 | 7.92 | 9.53 | 9.53 | 9.53 | |

| Sch 30 | 9.53 | 11.13 | 12.70 | 12.70 | 14.27 | |

| STD | 9.53 | 9.53 | 9.53 | 9.53 | 9.53 | |

| Sch 40 | 12.70 | 14.27 | 15.09 | … | 17.48 | |

| Sch 40S | 9.53 | 9.53 | 9.53 | … | 9.53 | |

| Sch 60 | 16.66 | 19.05 | 20.62 | 22.23 | 24.61 | |

| XS | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | |

| Sch 80 | 21.44 | 23.83 | 26.19 | 28.58 | 30.96 | |

| Sch 80S | 12.70 | 12.70 | 12.70 | … | 12.70 | |

| Sch 100 | 26.19 | 29.36 | 32.54 | 34.93 | 38.89 | |

| Sch 120 | 30.96 | 34.93 | 38.10 | 41.28 | 46.02 | |

| Sch 140 | 36.53 | 39.67 | 44.45 | 47.63 | 52.37 | |

| XXS | … | … | ||||

| Sch 160 | 40.49 | 45.24 | 50.01 | 53.98 | 59.54 | |

| NPS = Nominal Pipe Size O.D. = Outside Diameter | ||||||

| Dimensions are in millimeters unless otherwise indicated. | ||||||

| DIMENSIONAL TOLERANCES FOR SEAMLESS AND WELDED PIPES ASTM A530 | ||||||

| Nominal pipe size | ||||||

| up to 4 = ± 0.79 mm | 5 thru 8 = + 1.58 mm / – 0.79 mm | ||||||

| 10 thru 18 = + 2.37 mm / – 0.79 mm | 20 thru 24 = + 3.18 mm / – 0.79 mm | ||||||

| Wall Thickness | Length | Weight | ||||

| All Diameters = – 12.5% | + 6.40 mm / – 0 mm | Weight = + 10% / – 1.5% | ||||

| 26 inches to 48 inches | ||||||

| 26" > 48" | Wall Thickness and Weight | |||||

| NPS | OD | 5 | 5S | 10 | ||

| 26 | 660 | wt | 7.92 | |||

| kg/m | 127.36 | |||||

| 28 | 711 | wt | 7.92 | |||

| kg/m | 137.32 | |||||

| 30 | 762 | wt | 6.35 | 6.35 | 7.92 | |

| kg/m | 118.34 | 118.31 | 147.29 | |||

| 32 | 813 | wt | 7.92 | |||

| kg/m | 157.25 | |||||

| 34 | 864 | wt | 7.92 | |||

| kg/m | 167.21 | |||||

| 36 | 914 | wt | 7.92 | |||

| kg/m | 176.97 | |||||

| 38 | 965 | wt | ||||

| kg/m | ||||||

| 40 | 1016 | wt | ||||

| kg/m | ||||||

| 42 | 1067 | wt | ||||

| kg/m | ||||||

| 44 | 1118 | wt | ||||

| kg/m | ||||||

| 46 | 1168 | wt | ||||

| kg/m | ||||||

| 48 | 1219 | wt | ||||

| kg/m | ||||||

| 26 – 48 | Wall Thickness and Weight | |||||

| NPS | OD | 10S | 20 | 30 | ||

| 26 | 660 | wt | 12.70 | |||

| kg/m | 202.74 | |||||

| 28 | 711 | wt | 12.70 | 15.88 | ||

| kg/m | 218.71 | 272.23 | ||||

| 30 | 762 | wt | 7.92 | 12.70 | 15.88 | |

| kg/m | 132.91 | 234.68 | 292.20 | |||

| 32 | 813 | wt | 12.70 | 15.88 | ||

| kg/m | 250.65 | 312.17 | ||||

| 34 | 864 | wt | 12.70 | 15.88 | ||

| kg/m | 266.63 | 332.14 | ||||

| 36 | 914 | wt | 12.70 | 15.88 | ||

| kg/m | 282.29 | 351.73 | ||||

| 38 | 965 | wt | ||||

| kg/m | ||||||

| 40 | 1016 | wt | ||||

| kg/m | ||||||

| 42 | 1067 | wt | ||||

| kg/m | ||||||

| 44 | 1118 | wt | ||||

| kg/m | ||||||

| 46 | 1168 | wt | ||||

| kg/m | ||||||

| 48 | 1219 | wt | ||||

| kg/m | ||||||

| 26 – 48 | Wall Thickness and Weight | |||||

| NPS | OD | STD | 40 | XS | ||

| 26 | 660 | wt | 9.53 | 12.70 | ||

| kg/m | 152.88 | 202.74 | ||||

| 28 | 711 | wt | 9.53 | 12.70 | ||

| kg/m | 164.86 | 218.71 | ||||

| 30 | 762 | wt | 9.53 | 12.70 | ||

| kg/m | 176.85 | 234.68 | ||||

| 32 | 813 | wt | 9.53 | 17.48 | 12.70 | |

| kg/m | 188.83 | 342.94 | 250.65 | |||

| 34 | 864 | wt | 9.53 | 17.48 | 12.70 | |

| kg/m | 200.82 | 364.92 | 266.63 | |||

| 36 | 914 | wt | 9.53 | 19.05 | 12.70 | |

| kg/m | 212.57 | 420.45 | 282.29 | |||

| 38 | 965 | wt | 9.53 | 12.70 | ||

| kg/m | 224.56 | 298.26 | ||||

| 40 | 1016 | wt | 9.53 | 12.70 | ||

| kg/m | 236.54 | 314.23 | ||||

| 42 | 1067 | wt | 9.53 | 12.70 | ||

| kg/m | 248.53 | 330.21 | ||||

| 44 | 1118 | wt | 9.53 | 12.70 | ||

| kg/m | 260.52 | 346.18 | ||||

| 46 | 1168 | wt | 9.53 | 12.70 | ||

| kg/m | 272.70 | 361.84 | ||||

| 48 | 1219 | wt | 9.53 | 12.70 | ||

| kg/m | 284.25 | 377.81 | ||||

| NPS = Nominal Pipe Size | ||||||

| O.D. = Outside Diameter | ||||||

| WT = Walltickness | ||||||

| KG/M = Kilogram per meter | ||||||

| Dimensions are in millimeters unless otherwise indicated | ||||||

| Weights are in kilograms p/meter and approximately given | ||||||

Mr. Thi

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 982 384 688

Hotline/ Zalo/ Wechat:

+84 982 384 688

|

Ms. Hoa

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 982 803 586

Hotline/ Zalo/ Wechat:

+84 982 803 586

|

Ms. Phương

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 341

Hotline/ Zalo/ Wechat:

+84 971 567 341

|

Ms. Trinh

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 943

Hotline/ Zalo/ Wechat:

+84 971 567 943

|

Ms. Trân

Email:

theptangiabao@gmail.com

Email:

theptangiabao@gmail.com

|

Skype:

Skype:

|

Hotline/ Zalo/ Wechat:

+84 971 567 954

Hotline/ Zalo/ Wechat:

+84 971 567 954

|

Home

Home